Advanced pellet feed machine, efficient procurement

Advanced pellet feed machine, efficient procurement,

Advanced pellet feed machine, efficient procurement Efficient procurement of advanced pellet feed machinery Procurement strategy of advanced pellet feed machine Reliable supplier of advanced pellet feed machine Efficient procureme, efficient procurement Procurement of advanced pellet feed machinery Efficient procurement of advanced pellet feed machinery Purchase of high-quality pellet feed machine Supplier of advanced feed pelle,

Product Advantages

1. Simple structure, wide applicability, small footprint and low noise.

2. Powdered feed and grass powder can be granulated without (or a little) liquid addition. Therefore, the moisture content of pelleted feed is basically the moisture content of the material before pelleting, which is more conducive to storage.

3. The particles made by this machine have high hardness, smooth surface and sufficient internal curing, which can improve the digestion and absorption of nutrients, and can kill general pathogenic microorganisms and parasites. It is suitable for raising rabbits, fish, ducks and experimental animals. The economic benefits that can be obtained compared to mixed powdered feeds.

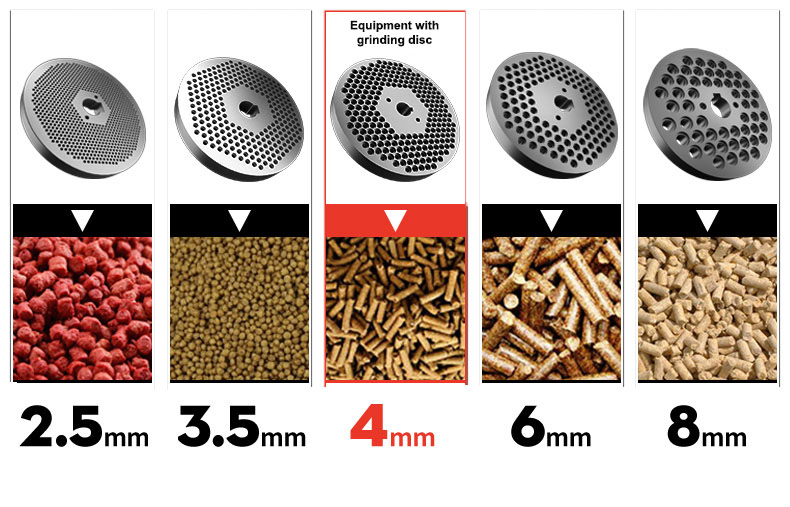

4. This model is equipped with 1.5-20 kinds of aperture molds, which are suitable for granulation of different materials and achieve the best effect.

5. Adapt to different materials to ensure the pressing effect. Compression molding of wood chips, corn stalks, etc. requires a lot of pressure. In the same kind of pelletizing equipment, the roller part is the central part of the whole equipment, and the alloy steel is used to improve the service life of the roller.

Specifications

| Model | Power(KW) | Yield(KG) | Rotating Sspeed | Dimensions(mm) | Weight |

| 120 | 3 | 40-50 | 320 | 1040*550*1140 | 68 |

| 150 | 4 | 75-125 | 320 | 1280*600*1250 | 92 |

| 210 | 11 | 200-250 | 320 | 1500*850*1400 | 189 |

| 260 | 15 | 350-500 | 380 | 1980*800*1600 | 300 |

| 300 | 18.5 | 500-800 | 380 | 2080*900*1750 | 410 |

| 400 | 37 | 1200-1500 | 400 | 2200*1200*1950 | 600 |

Instructions

1. The gearbox can be turned on after adding hyperbolic gear oil.

2. Install the pellet machine smoothly, check whether the steering meets the requirements, whether the screws in each part are loose, loosen the clearance adjustment screws on the roller axle seat, and make the feed machine in a no-load state, and it can be put into use after starting and running normally.

3. Before the new machine is used for the first time, take 10 catties of sawdust or grass powder vegetable oil or waste oil and mix it evenly, and then turn the clearance adjustment screw. Make the two rollers rotate at the same speed, gradually add the refueling feed, and at the same time continue to screw the adjusting screw of the pressing wheel until the material is slowly discharged, the extruded pellets are repeatedly squeezed to make the grinding hole smooth and smooth, and then the required mixed feed is processed. .

4. During feed processing, if there are more refined fibers, about 5% of water should be added. If there are too many concentrates in the mixed feed, the amount of water added can be reduced as appropriate. After processing, add a little oil that has been mixed with edible oil in advance. It is beneficial to start the machine next time and avoid the feed drying in the hole after the machine is stopped.

5. After processing, loosen the clearance adjustment screw to keep the roller in a free state. After the machine is stopped, remove the residual material accumulation in the upper and lower warehouses, especially the residual material at the bottom of the shaker to avoid damage to the bearing.

Our Factory

Introduction of Advanced Pellet Feed Machine: Improving the Efficiency and Quality of Animal Feed Production

Are you looking for reliable and high-performance solutions to simplify your animal feed production? Our new advanced pellet feed machine is your best choice. This cutting-edge equipment is designed to revolutionize the way you produce animal feed, helping you achieve unrivaled efficiency, productivity and quality.

With our advanced pellet feed machines, you can experience a seamless production process from start to finish. Featuring state-of-the-art technology and superior engineering, this machine is packed with innovative features that are sure to meet and exceed your expectations.

One of the most striking aspects of our machines is their exceptional efficiency. With its advanced motor and precision control, it can produce an excellent output of up to [insert specific amount] per hour. This impressive capacity will allow you to optimize production schedules and easily meet the growing demands of the market.

Additionally, our advanced pellet feed machines ensure precise and consistent quality from batch to batch. Equipped with advanced sensors and adjustable settings, the machine gives you fine-grained control over pellet size, shape and texture, ensuring optimal nutritional value and digestibility for a variety of animal species. Whether you are producing poultry, livestock or aquaculture feed, our machines ensure your animals receive the high-quality nutrition they need for optimal growth, health and performance.

Our advanced pellet feed machines not only excel in performance, but also stand out for durability and reliability. Constructed from high-quality materials and built to exacting standards, this robust machine can withstand the rigors of continuous operation, making it a long-term investment in your feed production facility. Its usability is further enhanced by its user-friendly interface and easy maintenance, enabling your operators to maximize productivity and minimize downtime.

Furthermore, we understand the importance of safety in feed production. That’s why our machines feature innovative safety features to protect your operators and maintain a safe work environment. From emergency stop buttons to safety guards, we’ve taken every step to safeguard the well-being of your employees while ensuring your operations operate at peak efficiency.

In conclusion, our advanced pellet feed machine is a game changer in the animal feed production industry. It combines cutting-edge technology, unrivaled efficiency and uncompromising quality to meet the changing needs of the modern feed producer. By investing in this state-of-the-art equipment, you can transform your production process to provide high-quality animal feed that keeps livestock and poultry healthier and more prosperous.

Experience the power of innovation and take your animal feed production to new heights with our advanced pellet feed machines. Contact us today to schedule a demo or learn more about this revolutionary solution for your business.