Application and prospect of double roll crusher, advantages of double roll crusher in ore crushing

Hebei Xingtang Huaicheng Machinery Equipment Co., Ltd.

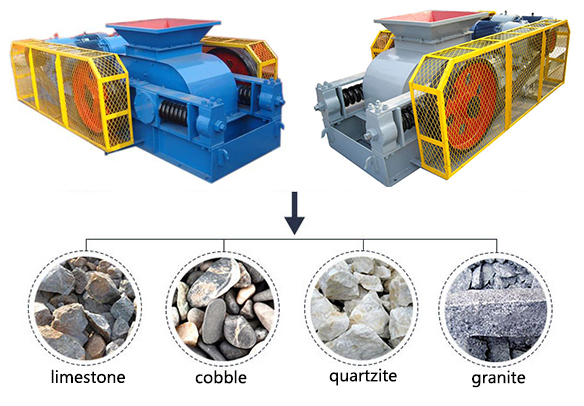

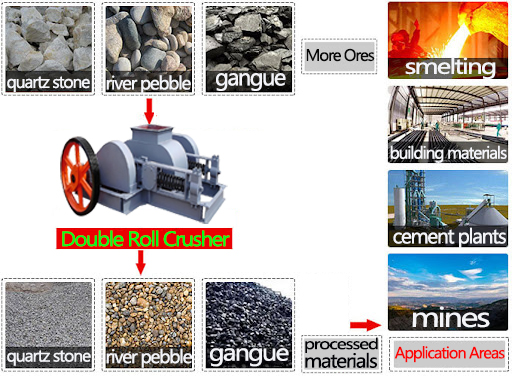

Double-roll crusher is a common crushing equipment, widely used in mining, metallurgy, chemical industry, building materials and other industries. It is mainly used for crushing medium-hard materials, with the advantages of large crushing ratio, high efficiency, simple structure and convenient maintenance.

Key attributes

| Product name | Double-roll crusher |

| Color | Customers' Requirements |

| Type | Roller Crusher |

| Condition | New |

| Key Selling Points | Easy to Operate |

| Warranty of core components | 1Year |

| Marketing Type | New Product |

| Machinery Test Report | Provided |

| Video outgoing-inspection | Provided |

| Place of Origin | Hebei, China |

Technical Parameters

| Specifications | Maximum feed size | Discharge port adjustment range | Production volume | Motor power | Weight |

| 2PGS-400*250 | 30 | 0-10 | 5-15 | 5.5*2 | 1.5 |

| 2PGS-400*400 | 40 | 0-10 | 8-20 | 7.5*2 | 2.2 |

| 2PGS-610*400 | 70 | 0-10 | 10-35 | 15*2 | 3.8 |

| 2PGS-750*500 | 85 | 0-10 | 15-45 | 18.5*2 | 5.5 |

| 2PGS-800*600 | 85 | 0-10 | 20-70 | 22*2 | 7.5 |

| 2PGS-1000*800 | 100 | 0-10 | 30-90 | 30*2 | 14.8 |

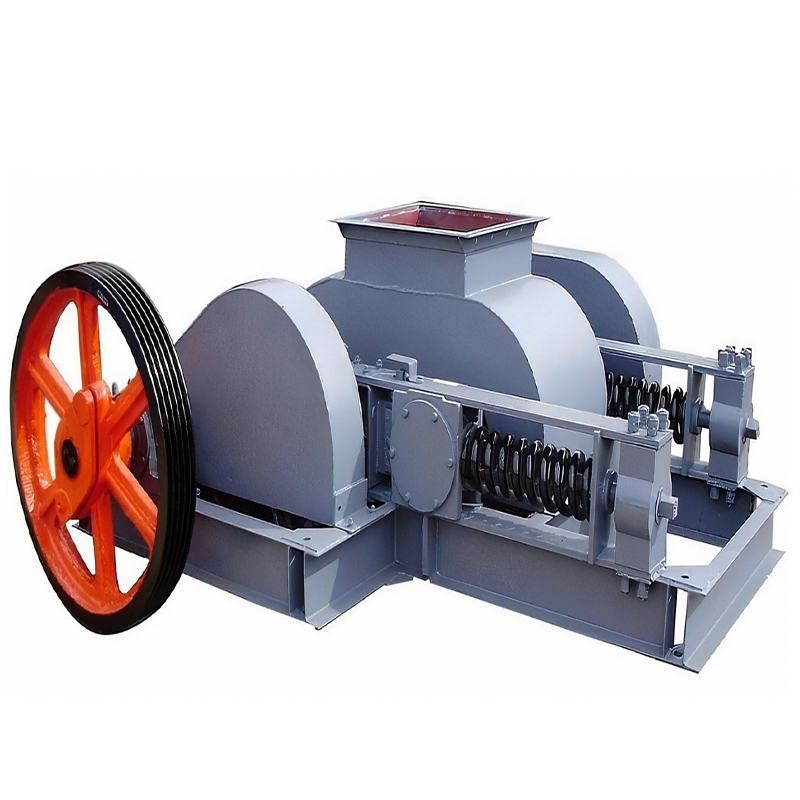

Working principle

Double-roll crusher uses extrusion force and shear force to crush materials through the relative rotation of two parallel crushing rollers. The material enters the crushing chamber from the feed port, is squeezed and ground between the two rollers, and is crushed into the required particle size and discharged from the discharge port.

Structural features

Crushing roller: The core component of the double-roll crusher, usually made of wear-resistant materials to increase service life. The roller surface can be smooth, grooved or with teeth to adapt to different materials and crushing requirements.

Adjustment device: By adjusting the gap between the crushing rollers, the size of the discharge particle size can be controlled. Common adjustment methods include wedge devices and hydraulic devices.

Driving device: Usually composed of a motor, a reducer and a coupling, the rollers are driven to rotate through a transmission device.

Protection device: Including overload protection device and safety protection device. When hard objects enter the crushing chamber or the equipment is overloaded, the protective device can effectively prevent equipment damage.

Main application

In the coal industry: the double-roll crusher is used for the crushing of raw coal. It can not only crush coal but also crush impurities in it, thereby improving the purity and utilization rate of coal.

In the building materials industry: the double-roll crusher is used for the crushing of materials such as limestone and slag to provide suitable raw materials for cement production.

Use and maintenance

Regular inspection: Regularly check the wear of the crushing rollers, bearings, transmission devices and other components, and replace the worn parts in time.

Lubrication and maintenance: Add lubricating oil to each lubrication point on time to keep the lubrication system clean and unobstructed.

Cleaning and maintenance: Regularly clean the dust and debris inside and around the crusher to keep the equipment clean.

Operating specifications: Operate the crusher in accordance with the requirements of the equipment manual to avoid overload operation and hard objects entering the crushing chamber.

Company Profile

The company is located in Xingtang Economic Development Zone, Shijiazhuang City, Hebei Province. The company has been committed to the research, design, development and manufacturing of various types of dust collectors, bale crushers, pellet machines, hammer crushers, jaw crushers, shredders, magnetic separators, vibrating screens, dryers, sand washers, conveyors and other mining and livestock equipment.

Technical Strength:Huaicheng Machinery has an efficient team of experienced engineers and technical experts, constantly pursuing technological innovation and product upgrades.

Manufacturing Process:Huaicheng Machinery has advanced production equipment and a strict quality control system to ensure that each equipment can meet customer requirements.

Customer Service:Huaicheng Machinery always puts customer needs first and takes it as its responsibility to meet customer needs.

FAQ

1. Who are we?

We are headquartered in Hebei, China, starting in 2020, selling to South Asia (20.00%), East Asia (20.00%), Middle East (10.00%),Southeast Asia (10.00%), North America (10.00%). There are about 201-300 people in our office in total.

2. How do we ensure quality?

Before mass production is always a pre-production sample;

Always conduct final inspection before shipment;

3. What can you buy from us?

Dust collector, magnetic extractor, linear vibrating screen, sand washing machine, drum dryer.

4. Why should you buy from us instead of other suppliers?

The company adheres to the concept of "technology first, integrity first" and has won the trust of our customers with

technology and product quality, reasonable prices, and timely service.

5. What services can we provide?

Accept delivery terms: CFR、CIF、EXW、CIP、FCA、DDP;

Accepted payment currencies: US dollars, euros, Japanese, Canadian dollars, Hong Kong dollars, British pounds, RMB;

Accepted payment methods: T/T, L/C, Western Union;

Spoken Languages: English, Chinese, Japanese

Company Profile

Customer Visit

Overseas Delivery

Exhibition

Feedback