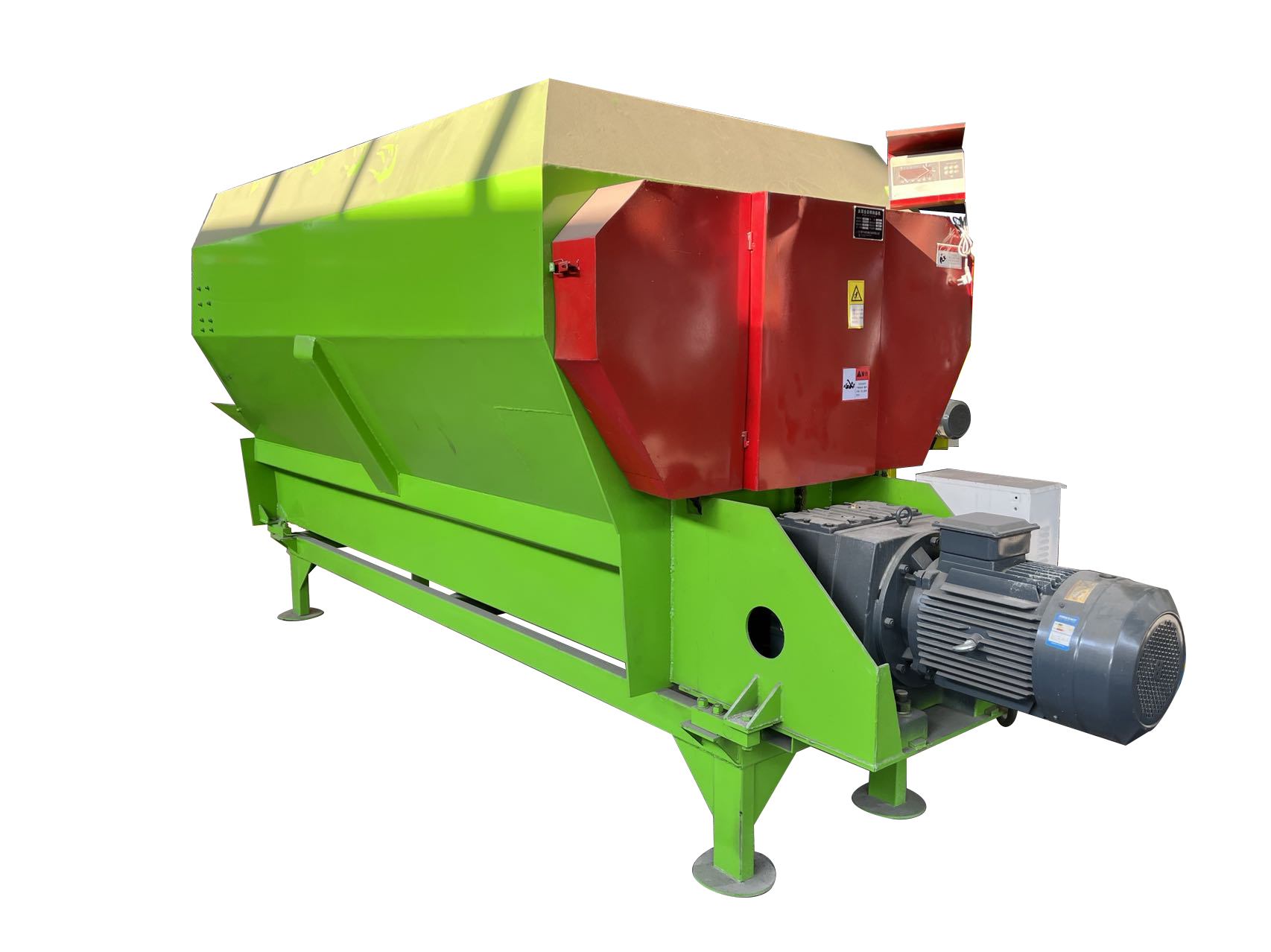

Efficient TMR feed preparation machine

Efficient TMR feed preparation machine,

Industrial TMR feed processing machine Affordable TMR feed preparation equipment Precision TMR feed mixer and processing machine Multifunctional TMR Feed Processing Machinery Robust TMR feed preparati,

Core Introduction

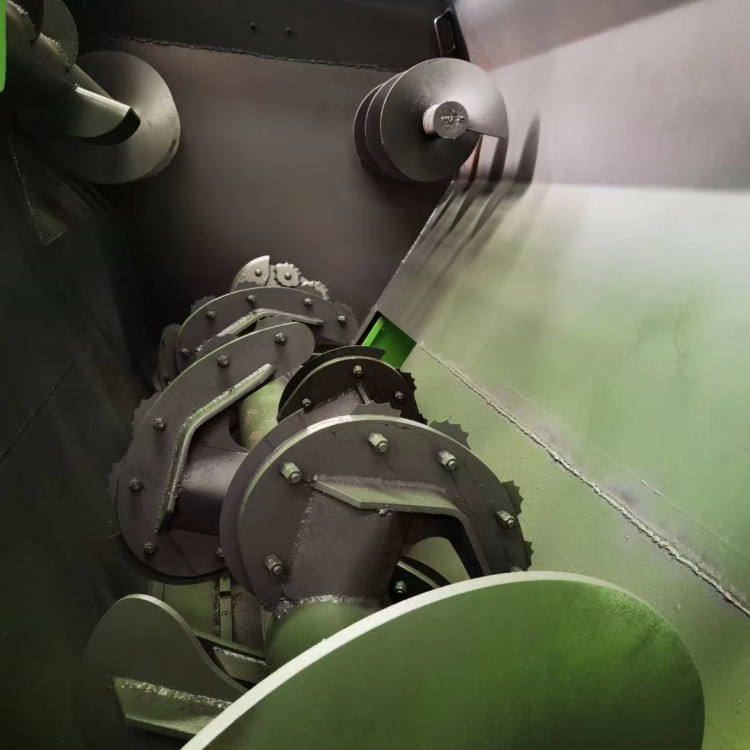

The total mixed ration mixer is mainly composed of one or two augers, and the spiral auger is divided into left-handed and right-handed. During mixing, cutting and stirring, the materials are rotated and stirred from all directions at both ends of the box to the middle of the mixer at the same time. Each helical lead on the screw body of the auger is equipped with a moving blade, which is used for cutting work with the fixed teeth on the center line of the feed mixer, cutting and stirring all kinds of fibrous forages and straws that pass through, so as to achieve full mixing with uniform pulverization and mixing. Dietary feeding effect.

TMR is the abbreviation of Total mixed rations in English. The TMR total mixed ration preparation machine is a feed processing equipment that integrates crushing, stirring and mixing. It can cut long grass, silage and other forages. Kneading silk, and can fully mix a coarse material, concentrate, minerals, microorganisms and other additives, can provide enough nutrition to meet the needs of dairy cows. On the basis of supporting technical measures and TMR machinery with excellent performance, TMR feeding technology can ensure that every ration eaten by dairy cows is a full-price diet with stable concentration of concentrate and coarseness and consistent nutrient concentration, which is a major change in the way of feeding dairy cows.

Compared with traditional feeding methods, TMR feeding has the following advantages: increasing the dry matter intake of dairy cows can eliminate the selectivity (picky eating) of dairy cows to a particular feed, which is conducive to maximizing the use of low-cost feed formulations . At the same time, TMR is completely mixed according to the proportion specified in the diet, which reduces the occasional lack or poisoning of trace elements and vitamins; improves milk quality; reduces the incidence of dairy cattle diseases; labor time, improve economic efficiency.

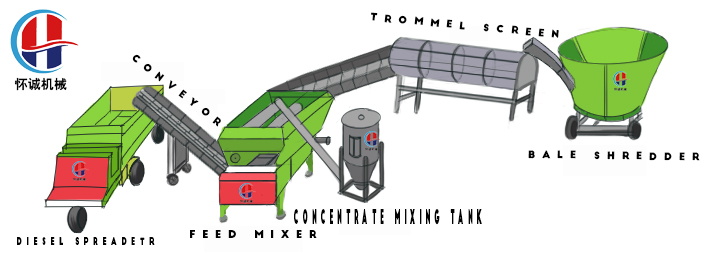

Mechanized farming case display:

After the automatic distribution box is opened, you can set the mixing time of the mixer, or set the default time, click Start, the mixer starts, the mixing starts to run, the grass enters the silo through the conveyor, the flour mill, and the fine material tank are opened simultaneously. After the fine material is mixed, it will automatically start feeding in the mixer. When the mixer is finished mixing, the hydraulic lifting door will automatically open and start discharging. At this time, the conveyor will automatically open and start running. The total length is 97 meters. After the material is discharged, the conveyor will stop running, and the bin door will be automatically closed. According to the degree of mixing of the grass, the reasonable mixing time can be appropriately modified and saved. When it is used next time, directly according to the Set the content and start with one key. The breeding system is our company in After the on-site inspection of the customer’s breeding factory, it was designed according to the customer’s requirements. The whole process of feeding cattle and sheep is automated, and the original drinking trough is replaced by a conveyor. It is also equipped with a water pump for water supply, a spray tower disinfection tank, cooling and disinfection, and a manure scraper. Carry out excrement cleaning work, save labor, and one person can feed hundreds of cows.

Show more details

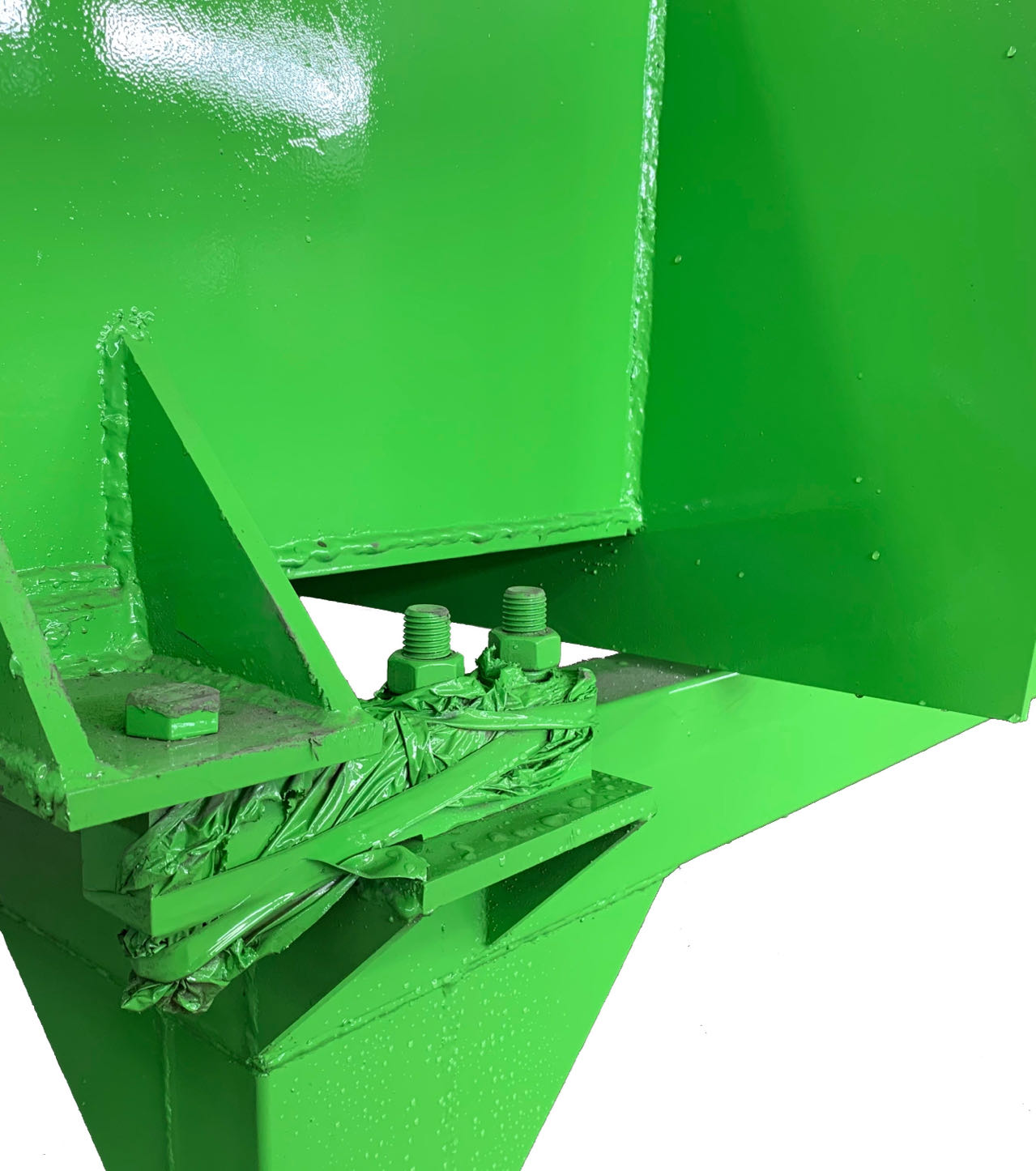

1. Safety distribution box: support one-button start, button operation, providing safety guarantee for the whole machine

2. Independent hydraulic lifting system: independent oil pump drives a small handle to control the speed of the hydraulic grass outlet

3. Electronic weighing sensor: 8 tons of high-precision electronic weighing sensor can accurately calculate the ratio of concentrate and forage to realize scientific farming

Advantages

1. The concentrated roughage is evenly mixed to improve the palatability of the feed and avoid the occurrence of picky eating and nutritional imbalance in dairy cows;

2. It is beneficial to the synthesis of carbohydrates and carbohydrates, and to improve the utilization rate of protein;

3. Enhance rumen function, maintain the stability of rumen pH value, and prevent rumen acidosis;

4. It can maximize the dry matter intake of dairy cows and improve the conversion rate of feed;

5. According to the quality and price of roughage, flexibly adjust and effectively utilize non-roughage;

6. Reduce labor, improve breeding efficiency, and make animal feeding management more accurate;

7. It can make full use of local raw material resources to reduce the cost of feed;

8. It is beneficial to the large-scale production of cattle farms;

9. Conducive to epidemic prevention of dairy farms and reduce the incidence of diseases.

Our Factory

In modern livestock farming, efficiency is key. Every farmer wants a system that saves time and effort while ensuring high quality feed for their animals. This is where the efficient TMR feed preparation machine comes in. Designed with the latest technological advancements, this innovative machine has revolutionized the way feed is prepared, making it easier and more efficient than ever.

At the heart of the efficient TMR feed preparation machine is a state-of-the-art device that combines cutting-edge technology with user-friendly features. Its main function is to accurately measure, mix and distribute total mixed ration (TMR) feed for livestock. Whether you have cattle, goats or any other animal, this machine will ensure they receive a balanced and nutritious diet that improves health and productivity.

One of the outstanding features of the high-efficiency TMR feed preparation machine is its unrivaled efficiency. The ability to process large quantities of feed in a short amount of time eliminates the need for manual mixing, which is time-consuming and prone to human error. By automating processes, farmers can save valuable time and focus on other important aspects of their operations, such as animal care and farm management.

Furthermore, this powerful machine is designed to handle a wide variety of feed ingredients. From hay and silage to grain and protein supplements, it efficiently blends all ingredients to create a consistent and well-distributed feed mix. This ensures that every animal receives the same nutritional value, resulting in even growth and improved overall performance.

Safety is another important aspect of an efficient TMR feed preparation machine. It incorporates advanced safety features to protect operators and animals. It is equipped with an emergency shut-off system and metal detectors to minimize the risk of accidents and ensure that no foreign objects or contaminants enter the feed.

In terms of user-friendliness, the efficient TMR feed preparation machine creates no confusion. Its intuitive interface and user-friendly controls allow farmers to easily adjust settings, monitor the mixing process and maintain the machine with minimal effort. Plus, its compact design saves valuable space and can be easily installed in any farm environment.

To further enhance convenience, the high-efficiency TMR feed preparation machine is equipped with intelligent software that provides data recording and analysis functions. This means farmers can track their feed usage, monitor nutrient content and make adjustments based on scientific data. This not only helps optimize feed costs, but also ensures optimal animal health and performance.

In conclusion, the efficient TMR feed preparation machine is a game changer in the livestock sector. By combining advanced technology, efficiency and maximum safety, it offers farmers an all-in-one solution for preparing highly nutritious feed for animals. Say goodbye to manual mixing and hello to a new era of productivity and convenience in agricultural production with the high-efficiency TMR feed preparation machine.