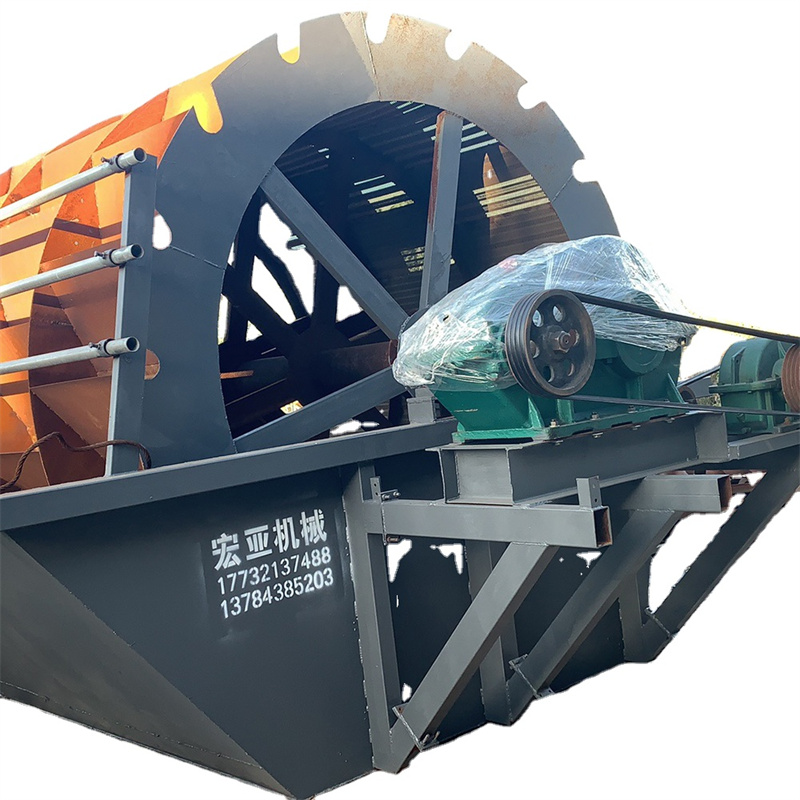

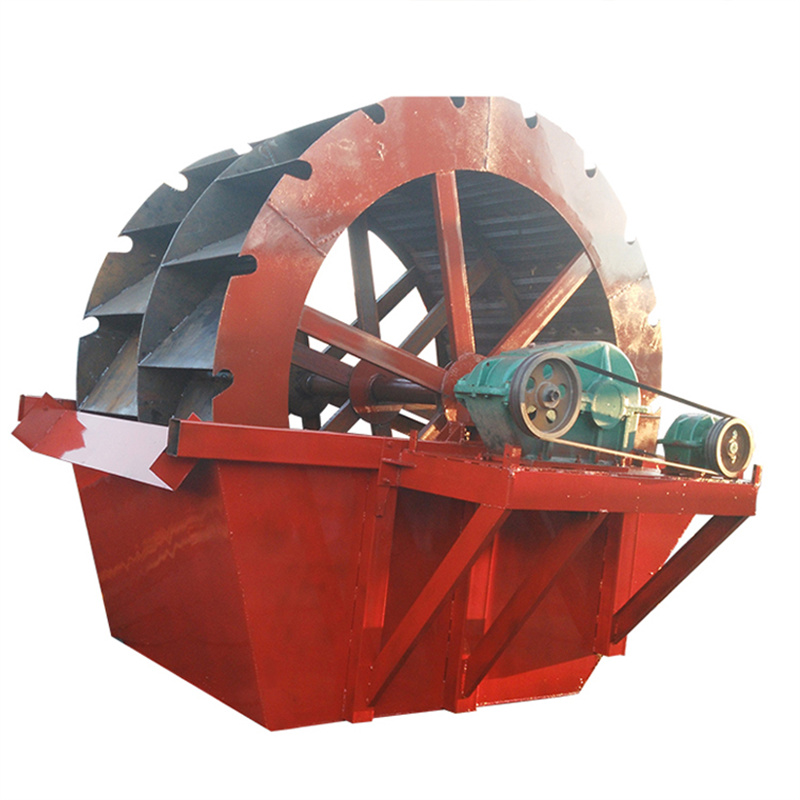

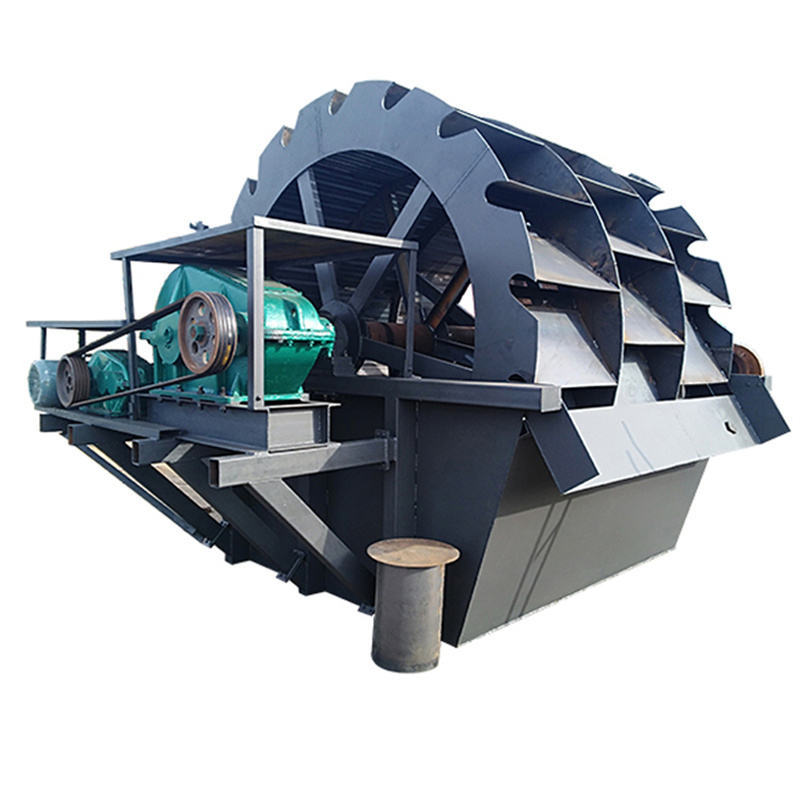

High-Efficiency Trough Sand Washing Machine

Core Introduction

nd washing machine: an indispensable item in the field of ore processing

Hebei Xingtang Huaicheng Machinery Equipment Co., Ltd.

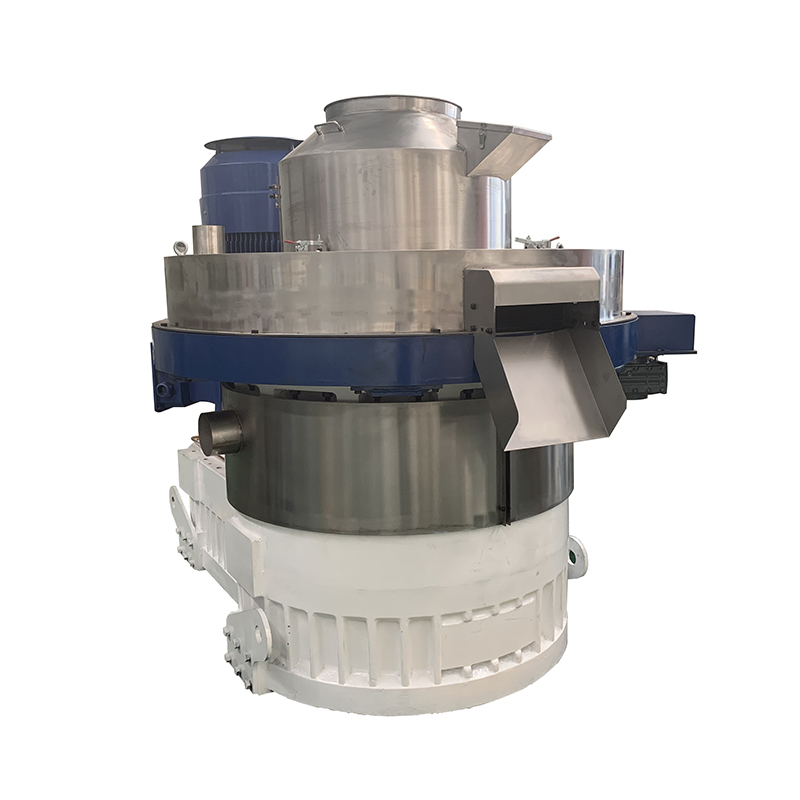

Sand washing machine is an important ore processing equipment, widely used in mining, construction, cement, chemical industry, metallurgy and other industries. Its main function is to separate impurities, soil, etc. in the ore through the action of mechanical force and water flow, thereby improving the grade and quality of the ore and meeting the production needs of different industries.

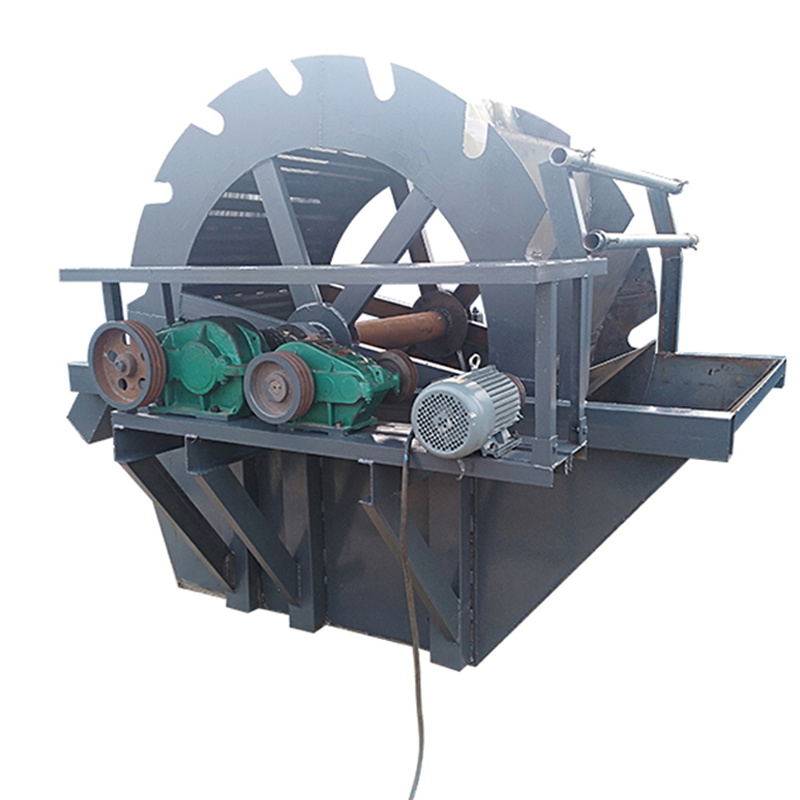

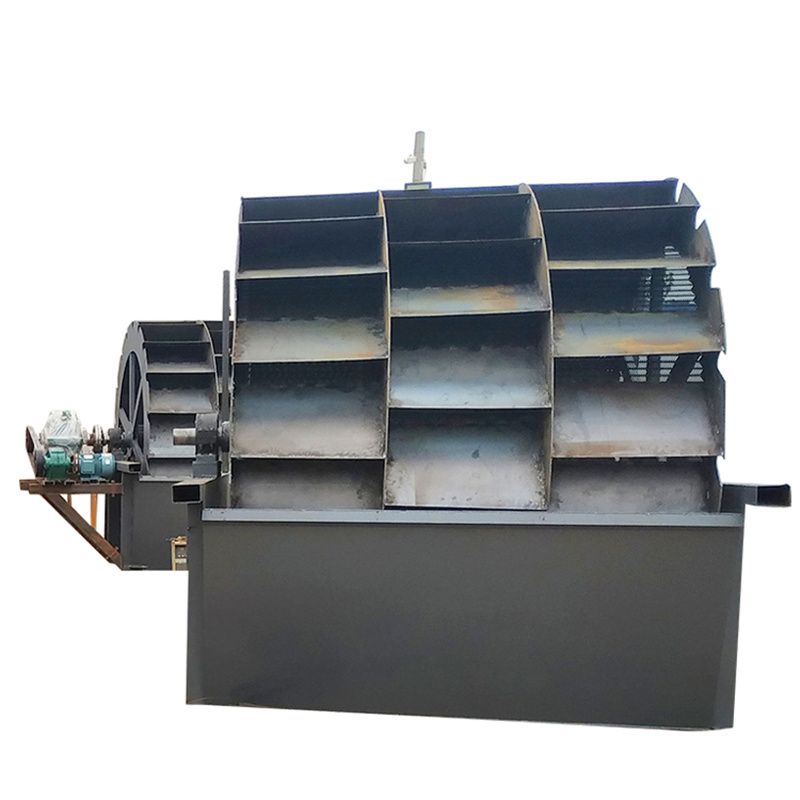

Sand washing machine working principle

The sand washing machine usually consists of a feeding device, a spiral impeller, a reducer, a drainage tank, a mud drainage tank and other components. When working, the ore enters the sand washing machine through the feeding device, and is continuously pushed forward and mixed with the water flow through the action of the spiral impeller. The soil and impurities in the ore are washed and separated by the water, and the lighter soil is washed out by the water. sand machine, while the heavier ore is deposited at the bottom. Finally, the cleaned ore is discharged from the drainage tank to complete the entire treatment process.

Application areas

Mining industry: Sand washing machines are widely used in the cleaning and separation of various types of ores, such as sand, coal mines, gold mines, etc., and play an important role in improving ore grade and reducing production costs.

Construction industry: Construction sites often need to clean sand, gravel and other materials for concrete mixing, road paving and other tasks. Sand washing machines can effectively remove impurities and ensure the quality of building materials.

Cement industry: A large amount of sand and gravel materials are used in the cement production process. Sand washing machines can help remove soil and impurities and improve the efficiency and quality of cement production.

Chemical industry: In the chemical production process, sand washing machines are used to clean raw materials, such as limestone, iron sulfide ore, etc., to ensure the smooth progress of subsequent production steps.

Metallurgical industry: In metallurgical production, sand washing machines are often used to process various ores, such as iron ore, manganese ore, etc., to improve the grade and extraction rate of the ore.

Advantages

1. Multiple functions, high cleanliness

The equipment has three functions of cleaning, dehydration and grading; when working, driven by the impeller, the sand and gravel grind each other to remove the impurities covering the surface of the sand and gravel, and at the same time destroy the water vapor layer covering the sand, and complete the cleaning in a strong water flow Cleaning function.

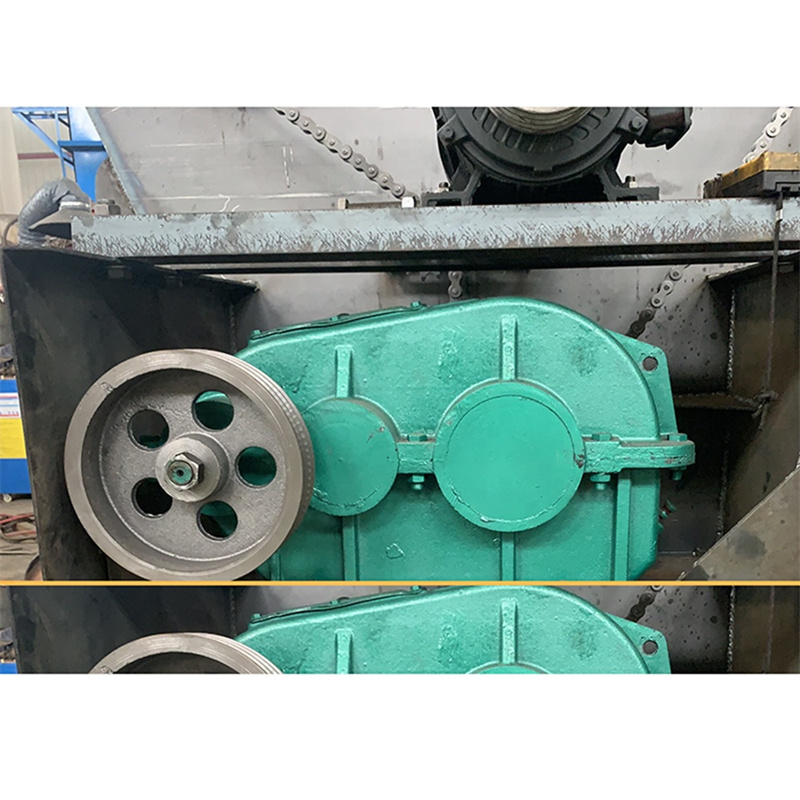

2. Simple structure and low failure rate

The sand washing machine has a simple and reasonable structure, the impeller drive bearing device is isolated from water and water-receiving materials, a novel sealing structure, and a fully enclosed oil bath transmission device, which greatly avoids the bearing damage caused by water immersion, sand and pollutants. occur.

3. Long service life and no pollution

Good structural layout and effective sealing design enable the machine to be durable without maintenance for a long time; low water consumption, low working noise, and compliance with national environmental protection standards.

Compared with traditional sand washing machines

The impeller sand washing machine has high cleaning degree, reasonable structure layout, large processing capacity and low power consumption. Its series of characteristics have proved that it will be the choice for upgrading the domestic sand washing industry

Company Profile

Customer Visit

Overseas Delivery

Exhibition

Feedback