LS screw conveyor: working principle and application, ideal choice for efficient material transportation

Working principle

LS screw conveyor drives the screw shaft to rotate through an electric motor, and relies on the thrust of the spiral blade to push the material from the feed end to the discharge end. During the conveying process, the material moves forward with the rotation of the spiral blade, thereby realizing the conveying of the material.

Structural composition

Conveying pipe: mainly used to contain materials and support the spiral body, usually made of metal materials.

Spiral body: It is the core component of the conveyor, consisting of spiral blades and spiral shafts. The spiral blades can be solid blades or ribbon blades, and the specific form depends on the nature of the conveyed material and the conveying requirements.

Driving device: including electric motors, reducers, etc., used to provide the rotational power of the spiral body.

Support structure: including intermediate hanging bearings, front and rear end bearings, etc., used to support the spiral shaft to ensure its stable operation during the conveying process.

Features and advantages

Simple structure: simple design, easy to manufacture and maintain.

Convenient operation: stable operation, high degree of automation, easy operation.

Good sealing: The conveying pipe has good sealing performance and can effectively prevent material leakage and external pollution.

Strong adaptability: It can be flexibly designed according to different material properties and conveying requirements, and has a wide range of adaptability.

Small footprint: The conveyor has a compact structure and occupies a small space, which is suitable for installation and use in small venues.

Application range

Building materials industry: used for the transportation of materials such as cement, sand, gravel, lime, etc.

Chemical industry: used for the transportation of chemical raw materials, fertilizers and other materials.

Metallurgical industry: used for the transportation of mineral powder, coal powder and other materials.

Grain industry: used for the transportation of materials such as grain and feed.

Environmental protection industry: used for the transportation and treatment of materials such as sludge and garbage.

Maintenance and maintenance

Regular inspection: Regularly check the wear and lubrication of key components such as spiral bodies, bearings, and drive devices.

Lubrication maintenance: Add lubricating oil to bearings, reducers and other components on time to ensure good lubrication.

Tightening inspection: Check the tightness of each connection to prevent looseness from affecting equipment operation.

Cleaning materials: Regularly clean the residual materials in the conveying pipe to prevent material accumulation from affecting the conveying efficiency.

Conclusion

LS type screw conveyor has been widely used in various industrial productions due to its simple structure, convenient operation and strong adaptability. Through reasonable maintenance and care, the service life of the equipment can be effectively extended, the conveying efficiency can be improved, and reliable protection can be provided for the production process.

Company Profile

Customer Visit

Overseas Delivery

Exhibition

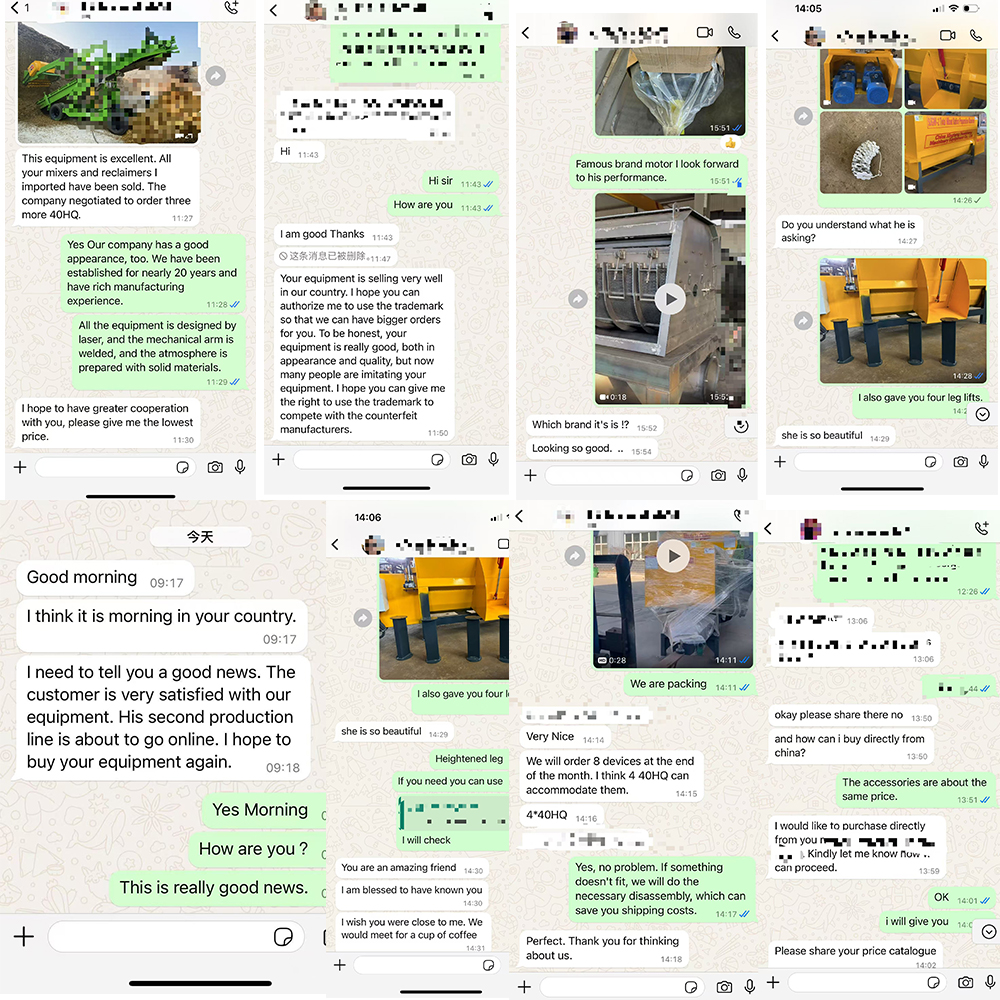

Feedback