Magnetic Ore Separator - Tmr Horizontal Feed Mixer Feed Mixer Kneading Wire Cutting Mixing Machine – Xingtang Huaicheng

Magnetic Ore Separator - Tmr Horizontal Feed Mixer Feed Mixer Kneading Wire Cutting Mixing Machine – Xingtang Huaicheng Detail:

Core Introduction

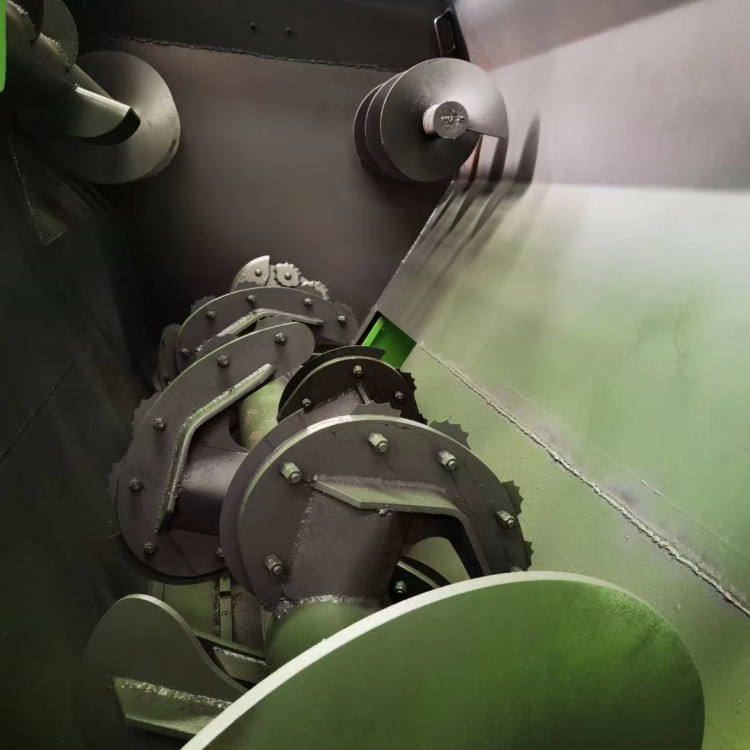

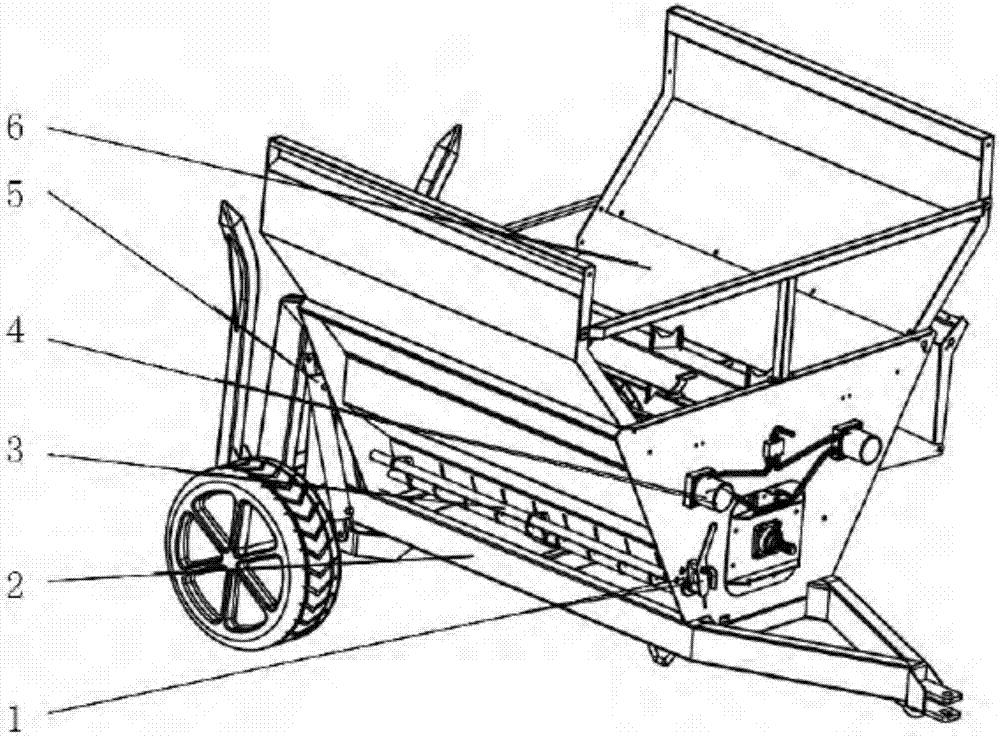

The total mixed ration mixer is mainly composed of one or two augers, and the spiral auger is divided into left-handed and right-handed. During mixing, cutting and stirring, the materials are rotated and stirred from all directions at both ends of the box to the middle of the mixer at the same time. Each helical lead on the screw body of the auger is equipped with a moving blade, which is used for cutting work with the fixed teeth on the center line of the feed mixer, cutting and stirring all kinds of fibrous forages and straws that pass through, so as to achieve full mixing with uniform pulverization and mixing. Dietary feeding effect.

TMR is the abbreviation of Total mixed rations in English. The TMR total mixed ration preparation machine is a feed processing equipment that integrates crushing, stirring and mixing. It can cut long grass, silage and other forages. Kneading silk, and can fully mix a coarse material, concentrate, minerals, microorganisms and other additives, can provide enough nutrition to meet the needs of dairy cows. On the basis of supporting technical measures and TMR machinery with excellent performance, TMR feeding technology can ensure that every ration eaten by dairy cows is a full-price diet with stable concentration of concentrate and coarseness and consistent nutrient concentration, which is a major change in the way of feeding dairy cows.

Compared with traditional feeding methods, TMR feeding has the following advantages: increasing the dry matter intake of dairy cows can eliminate the selectivity (picky eating) of dairy cows to a particular feed, which is conducive to maximizing the use of low-cost feed formulations . At the same time, TMR is completely mixed according to the proportion specified in the diet, which reduces the occasional lack or poisoning of trace elements and vitamins; improves milk quality; reduces the incidence of dairy cattle diseases; labor time, improve economic efficiency.

Advantages

1. The concentrated roughage is evenly mixed to improve the palatability of the feed and avoid the occurrence of picky eating and nutritional imbalance in dairy cows;

2. It is beneficial to the synthesis of carbohydrates and carbohydrates, and to improve the utilization rate of protein;

3. Enhance rumen function, maintain the stability of rumen pH value, and prevent rumen acidosis;

4. It can maximize the dry matter intake of dairy cows and improve the conversion rate of feed;

5. According to the quality and price of roughage, flexibly adjust and effectively utilize non-roughage;

6. Reduce labor, improve breeding efficiency, and make animal feeding management more accurate;

7. It can make full use of local raw material resources to reduce the cost of feed;

8. It is beneficial to the large-scale production of cattle farms;

9. Conducive to epidemic prevention of dairy farms and reduce the incidence of diseases.

Our Factory

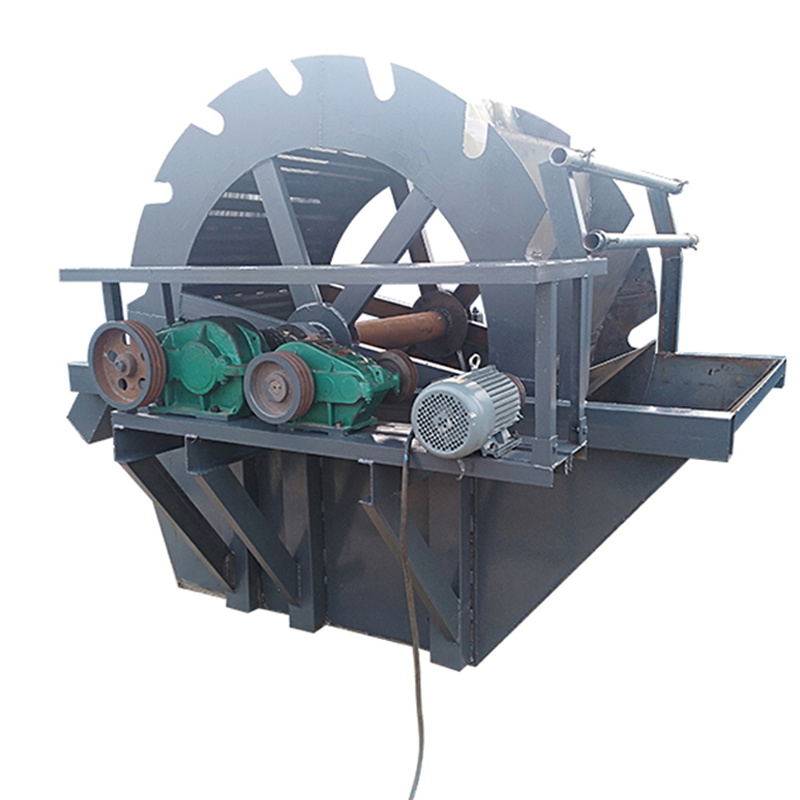

Product detail pictures:

Related Product Guide:

"Based on domestic market and expand overseas business" is our development strategy for Magnetic Ore Separator - Tmr Horizontal Feed Mixer Feed Mixer Kneading Wire Cutting Mixing Machine – Xingtang Huaicheng , The product will supply to all over the world, such as: Bhutan, Iraq, Spain, Our products are widely recognized and trusted by users and can meet continuously developing economic and social needs. We welcome new and old customers from all walks of life to contact us for future business relationships and achieving mutual success!

The company comply with the contract strict, a very reputable manufacturers, worthy a long-term cooperation.