Mixing Machine - Xwd Cycloid Needle Teeth Meshing Planetary Transmission Gear Reducer – Xingtang Huaicheng

Mixing Machine - Xwd Cycloid Needle Teeth Meshing Planetary Transmission Gear Reducer – Xingtang Huaicheng Detail:

Core Introduction

The use of cycloid reducer:

The cycloidal pinwheel reducer adopts the principle of cycloid pin-tooth meshing and planetary transmission, so it is usually called a planetary cycloid reducer. The planetary cycloidal pinwheel reducer can be widely used in petroleum, environmental protection, chemical industry, cement, transportation, Textile, pharmaceutical, food, printing, hoisting, mining, metallurgy, construction, power generation and other industries, as a drive or deceleration device, the machine is divided into horizontal, vertical, biaxial and direct-connected assembly methods. Its unique stable structure can replace ordinary cylindrical gear reducers and worm gear reducers in many cases. Therefore, planetary cycloid reducers are widely used in various industries and fields, and are generally welcomed by the majority of users.

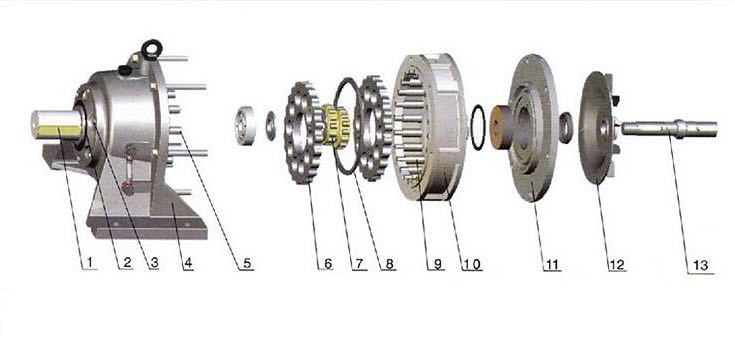

The cycloidal pinwheel reducer is a novel transmission device that applies the principle of planetary transmission and adopts the meshing of cycloid pin teeth. The entire transmission device of the cycloid reducer can be divided into three parts: the input part, the deceleration part, and the output part. A double eccentric sleeve with a dislocation of 180° is installed on the input shaft, and two roller bearings called swing arms are installed on the eccentric sleeve to form the H mechanism and the center hole of the two cycloidal wheels is the upper swing arm bearing of the eccentric sleeve The raceway, and the cycloidal wheel meshes with a group of annularly arranged needle teeth on the needle gear to form an internal meshing deceleration mechanism with a tooth difference of one tooth (in order to reduce friction, in a reducer with a small speed ratio , with needle sleeves on the needle teeth).

|

1 |

Output Shaft |

|

2 |

Output shaft tightening ring |

|

3 |

Small End Cap |

|

4 |

Machine Base |

|

5 |

Pin Bushing |

|

6 |

Cycloid |

|

7 |

Eccentric bearing |

|

8 |

Spacer Ring |

|

9 |

Pin-tooth pin pin-tooth sleeve |

|

10 |

Needle Housing |

|

11 |

Big End Cap |

|

12 |

Fan Blade Hood |

|

13 |

Input Shaft |

Our Factory

Product detail pictures:

Related Product Guide:

We have quite a few great team customers very good at internet marketing, QC, and dealing with kinds of troublesome trouble while in the output approach for Mixing Machine - Xwd Cycloid Needle Teeth Meshing Planetary Transmission Gear Reducer – Xingtang Huaicheng , The product will supply to all over the world, such as: Georgia, California, Denmark, Our company always concentrate on the development of the international market. We now have a lot of customers in Russia , European countries, the USA, the Middle East countries and Africa countries. We always follow that quality is foundation while service is guarantee to meet all customers.

We have been looking for a professional and responsible supplier, and now we find it.