Mine Drying Machine Introduction

The mine drying machine, also known as a mining dryer or rotary drum dryer, is a device widely used in the fields of building materials, metallurgy, chemicals, cement industry, etc. It is mainly used for drying materials such as slag, limestone, coal powder, clay, and so on. The following is a detailed introduction to the mine drying machine:

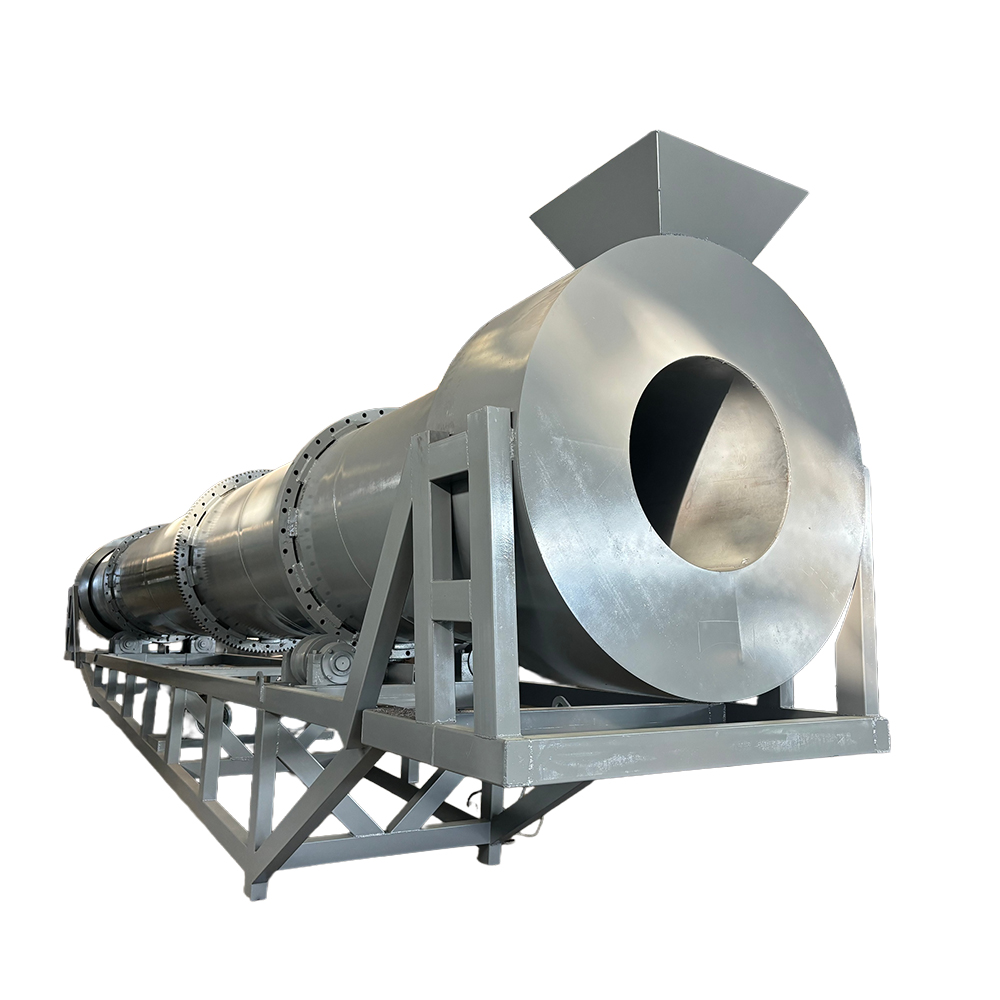

Structure Composition: The mine drying machine mainly consists of a rotating body, lifting plates, a transmission device, a support device, and sealing rings. Among them, the rotating body is the main part of the dryer, and the lifting plates are used to evenly distribute and disperse the material inside the drum to improve drying efficiency.

Working Principle: After wet material is added to the dryer, it is evenly distributed and dispersed inside the drum under the action of the evenly arranged lifting plates (also known as copying plates). It fully contacts with the co-current (or countercurrent) hot air, thereby accelerating the heat and mass transfer for drying. The material, under the action of the inclined lifting plates and hot air flow, moves in a controlled manner to the other end of the dryer and is discharged as finished product through a star-shaped discharge valve.

Product Characteristics: The mine drying machine has the advantages of reasonable structure, excellent craftsmanship, high output, low energy consumption, and convenient operation. It is suitable for drying large particles and heavy materials in the chemical, mining, metallurgical, and other industries, such as ores, blast furnace slag, coal, metal powders, phosphate fertilizers, ammonium sulfate, etc. At the same time, it can also meet the drying needs of powdered and granular materials with special requirements.

Usage Method

The usage method of the mine drying machine mainly includes the following steps:

Installation and Commissioning: The equipment should be installed on a level concrete foundation and fixed with anchor bolts. During installation, attention should be paid to ensuring that the main body of the machine is vertical to the horizontal plane, and checking whether the bolts in various parts are loose and whether the host compartment doors are tightly secured. After installation, conduct a no-load test run, and if the test run is normal, production can begin.

Preheating and Feeding: Ignite the hot air furnace for preheating, and simultaneously start the dryer. It is prohibited to heat the cylinder without rotating it to prevent cylinder bending. Gradually add wet material to the drying cylinder according to the preheating situation, and gradually increase the feed rate based on the moisture content of the discharged material.

Operation and Maintenance: During operation, the support roller frame should be filled with cooling water, and the lubrication points should be oiled in a timely manner. Pay attention to checking the wear degree of easily worn parts and replace worn parts as needed. At the same time, regularly check and replenish lubricating oil to ensure the normal operation of the equipment.

Shutdown and Cooling: When shutting down, the hot air furnace should be extinguished first, and the drying cylinder should continue to rotate until it cools down to nearly the ambient temperature before stopping. It is prohibited to shut down at high temperatures to prevent cylinder bending and deformation. In the event of a sudden power outage, the hot air furnace should be immediately extinguished, feeding should be stopped, and the cylinder should be turned half a turn at intervals until it cools down.

After-sales Maintenance

After-sales maintenance of the mine drying machine is key to ensuring its long-term stable operation and extending its service life. The following are some recommended maintenance measures:

Comprehensive Inspection: Regularly conduct a comprehensive inspection of the mine drying machine, including checking for corrosion of the equipment, looseness of connections, and whether gears and other consumable parts need to be replaced. This helps to timely discover and address potential issues and prevent failures.

Cleaning Work: Regularly clean the entire machine, motor, and filter screen to maintain the machine’s ventilation and heat dissipation. The filter screen is an important component that prevents dust and debris from entering the equipment, and it should be cleaned frequently to keep it unblocked.

Lubrication Maintenance: Regularly lubricate the transmission parts to reduce wear and failure. The quality and quantity of lubricating oil are crucial to the operation of the equipment, and it should be regularly checked, added, or replaced.

Temperature and Airflow Control: Reasonably set the temperature and airflow of the dryer based on the type and moisture content of the ore. Ensure that the temperature is not too high, which could damage the equipment or increase energy consumption, and not too low, which could affect drying efficiency. At the same time, maintain stable airflow to ensure sufficient contact between the hot air and the ore.

Rain and Dust Prevention Measures: When the dryer is not in use, the power should be turned off in a timely manner, and rain and dust prevention measures should be taken to protect the equipment from the impact of harsh environmental conditions.

Training and Technical Support: Regularly train operators on equipment operation and maintenance to improve their operational skills and troubleshooting abilities. At the same time, establish a long-term technical support and consultation relationship with the equipment supplier to promptly obtain professional technical support and solutions in the event of equipment failures.

In summary, proper use and maintenance of the mine drying machine can ensure its normal operation and extend its service life. During use, please pay attention to safety and operate according to the instructions.

Company Profile

Hebei Xingtang Huaicheng Machinery Equipment Co., Ltd. is an enterprise that integrates design, development, manufacturing, engineering installation, and after-sales service. Our company has advanced production equipment, strong technical strength, complete testing equipment, and strict management system, and is a designated backbone enterprise in the livestock machinery industry.

Our company specializes in producing various models of TMR fully mixed feed preparation machines, solid fertilizer trucks, liquid fertilizer trucks, manure cleaning trucks, feeding trucks, silage reclaimers, throwing trucks, grass bundle crushers, constant temperature drinking water tanks, cow neck shackles, cow beds, cow body brushes, various accessories and other livestock facilities and agricultural machinery.

Our company provides a one-stop service from cattle farm design to installation. No matter where the customer is, our technical personnel will personally conduct technical training on site to improve their operation and maintenance skills and promote harmonious development. Our pursuit is to be innovative, and our aim is to focus on management and improve quality. Hebei Xingtang Huaicheng Machinery Equipment Co., Ltd. sincerely hopes to cooperate with distributors and sister enterprises to achieve common development and contribute to serving agriculture, rural areas and farmers!

Contact phone number: +86-115613312872 (same as WeChat)

Pack and ship

The machine is wrapped in film, which is effectively waterproof and dustproof. When the machines arrive at your facility, they will be clean and brand new.

FAQ

1. Who are we?

We are headquartered in Hebei, China, starting in 2020, selling to South Asia (20.00%), East Asia (20.00%), Middle East (10.00%),Southeast Asia (10.00%), North America (10.00%). There are about 201-300 people in our office in total.

2. How do we ensure quality?

Before mass production is always a pre-production sample;

Always conduct final inspection before shipment;

3. What can you buy from us?

Dust collector, magnetic extractor, linear vibrating screen, sand washing machine, drum dryer.

4. Why should you buy from us instead of other suppliers?

The company adheres to the concept of “technology first, integrity first” and has won the trust of our customers with

technology and product quality, reasonable prices, and timely service.

5. What services can we provide?

Accept delivery terms: CFR、CIF、EXW、CIP、FCA、DDP;

Accepted payment currencies: US dollars, euros, Japanese, Canadian dollars, Hong Kong dollars, British pounds, RMB;

Accepted payment methods: T/T, L/C, Western Union;

Spoken Languages: English, Chinese, Japanese

Post time: Dec-30-2024