Hebei Huaicheng Machinery Equipment Co., Ltd.

Grass cutting machinery

The grass cutting machine is mainly used for cutting crop straw and grass, as most of its shredding is coarse feed, suitable for livestock farmers such as cattle and sheep. Generally speaking, grass cutters are divided into two types: electric motors and diesel engine trailers, and can also be equipped with gasoline or diesel engines. During use, daily maintenance and troubleshooting require the attention offarmers.

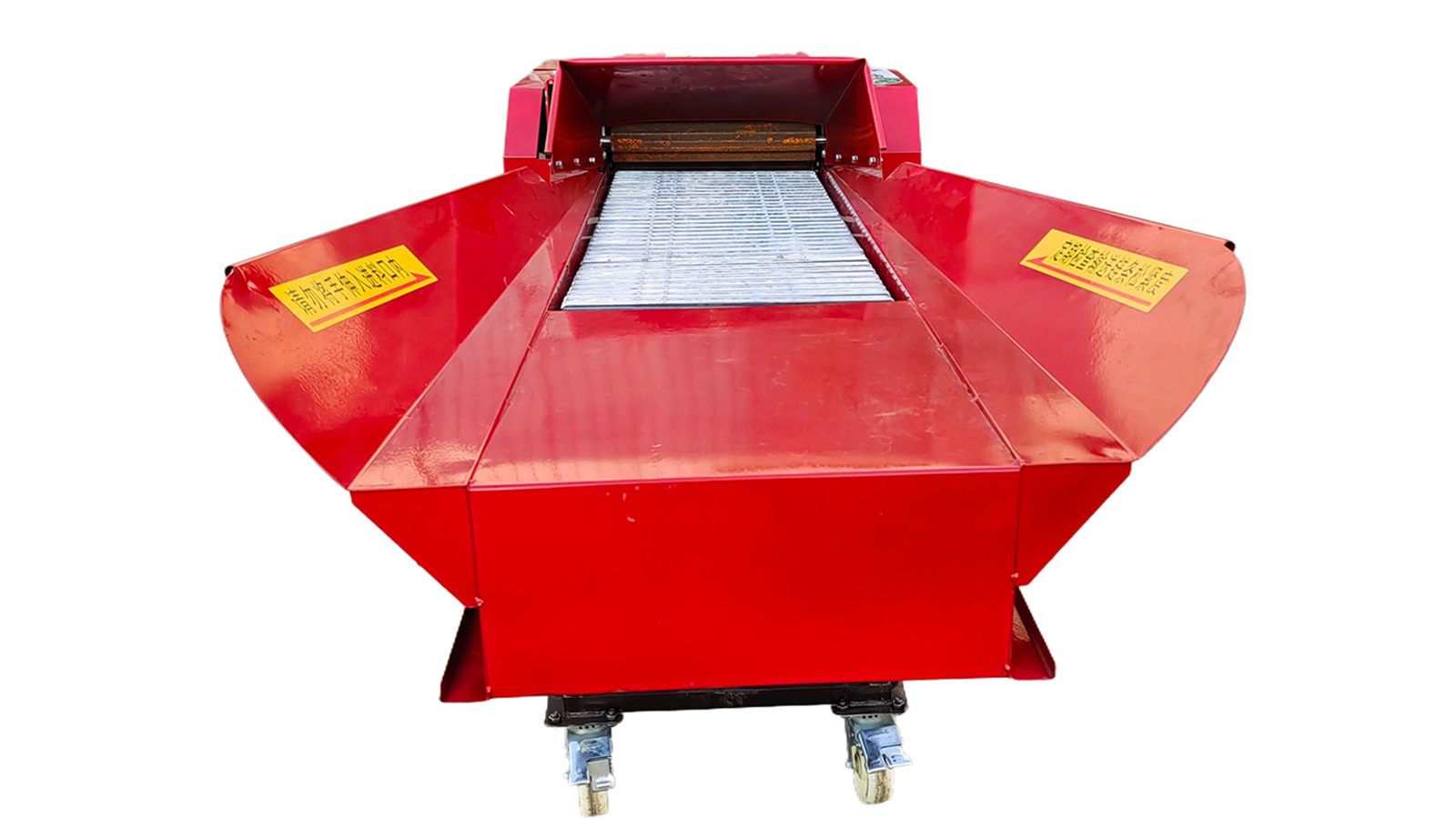

Machine Introduction

A grass cutting machine is a feed processing equipment that uses corn straw, wheat straw, rice straw and other crops as processing materials. Through mechanical crushing such as cutting and slicing, it produces feed suitable for livestock breeding of cattle, sheep, horses, and deer.

It mainly consists of feeding mechanism, cutting mechanism, throwing mechanism, transmission mechanism, walking mechanism, protective device, and frame. Its components are as follows:

Feeding mechanism: mainly composed of feeding platform, upper and lower blades, fixed blade, and fixed blade support seat.

Cutting and throwing mechanism: mainly composed of moving knife, cutting disc, locking screw, etc

Transmission mechanism: mainly composed of V-belts, transmission shafts, gears, universal joints, etc

Walking mechanism: mainly composed of ground casters

Protective device: composed of a protective cover。

1. Regularly check whether all fasteners are loose and tighten them.

2. Strengthen the maintenance of bearing seats, couplings, and transmission boxes, and regularly add or replace lubricating oil and grease.

3. The price of a grass cutting machine with adjustable cutting gap should be adjusted reasonably according to the thickness of the crop stem to ensure the normal operation of the grass cutting machine.

4. When the blade edge is found to be dull, use an oilstone to grind the moving blade.

5. After completing each shift’s homework, dust and dirt on the machine should be promptly removed; After each season’s homework is completed, the machine should be cleaned of debris, rust proof oil should be applied to the working parts, and placed indoors in a ventilated and dry place.

Precautions for use

During the operation of the grass cutting machine, safety protection equipment must be complete.

Operators must fully understand the performance of the machine, and it is strictly prohibited to start the machine after drinking alcohol, being sick, or being excessively fatigued. People and objects must not approach the operating parts during work.

Teenagers under the age of 16 and those who have not mastered the rules for using machines are not allowed to work alone.

The working area of the grass cutter should be spacious and equipped with fire prevention equipment.

When feeding grass, the operator should stand on the side of the feeding hopper and is strictly prohibited from reaching into the protective cover of the feeding hopper with both hands. At the same time, it is necessary to strictly prevent wooden sticks, metal objects, bricks and stones from entering the machine by mistake, in order to avoid damaging the machine and injuring people.

It is strictly prohibited to reverse the cutterhead.

The grass cutter must operate at the specified speed, and overspeed or overload operations are strictly prohibited.

When replacing fasteners for moving and fixed blades, grade 8.8 bolts and grade 8 nuts must be used, and low-grade bolts and nuts must not be used as substitutes.

If any abnormal noise is found during work, the machine should be stopped immediately for inspection. Before inspection, the power must be cut off and troubleshooting is prohibited while the machine is running.

The feeding amount of materials should be appropriate, as excessive feeding can easily cause overloading and stoppage. Of course, it cannot be too little, as too little will affect the cutting efficiency.

Before stopping work, the shift handle should be turned to position 0 and the machine should be idle for about 2 minutes. After blowing away the dust and weeds inside the machine, the machine should be stopped.

Company Profile

Hebei Xingtang Huaicheng Machinery Equipment Co., Ltd. is an enterprise that integrates design, development, manufacturing, engineering installation, and after-sales service. Our company has advanced production equipment, strong technical strength, complete testing equipment, and strict management system, and is a designated backbone enterprise in the livestock machinery industry.

Our company specializes in producing various models of TMR fully mixed feed preparation machines, solid fertilizer trucks, liquid fertilizer trucks, manure cleaning trucks, feeding trucks, silage reclaimers, throwing trucks, grass bundle crushers, constant temperature drinking water tanks, cow neck shackles, cow beds, cow body brushes, various accessories and other livestock facilities and agricultural machinery.

Our company provides a one-stop service from cattle farm design to installation. No matter where the customer is, our technical personnel will personally conduct technical training on site to improve their operation and maintenance skills and promote harmonious development. Our pursuit is to be innovative, and our aim is to focus on management and improve quality. Hebei Xingtang Huaicheng Machinery Equipment Co., Ltd. sincerely hopes to cooperate with distributors and sister enterprises to achieve common development and contribute to serving agriculture, rural areas and farmers!

Contact phone number: +86-115613312872 (same as WeChat)

Pack and ship

The machine is wrapped in film, which is effectively waterproof and dustproof. When the machines arrive at your facility, they will be clean and brand new.

FAQ

1. Who are we?

We are headquartered in Hebei, China, starting in 2020, selling to South Asia (20.00%), East Asia (20.00%), Middle East (10.00%),Southeast Asia (10.00%), North America (10.00%). There are about 201-300 people in our office in total.

2. How do we ensure quality?

Before mass production is always a pre-production sample;

Always conduct final inspection before shipment;

3. What can you buy from us?

Dust collector, magnetic extractor, linear vibrating screen, sand washing machine, drum dryer.

4. Why should you buy from us instead of other suppliers?

The company adheres to the concept of “technology first, integrity first” and has won the trust of our customers with

technology and product quality, reasonable prices, and timely service.

5. What services can we provide?

Accept delivery terms: CFR、CIF、EXW、CIP、FCA、DDP;

Accepted payment currencies: US dollars, euros, Japanese, Canadian dollars, Hong Kong dollars, British pounds, RMB;

Accepted payment methods: T/T, L/C, Western Union;

Spoken Languages: English, Chinese, Japanese

Post time: Dec-07-2024