Hebei Xingtang Huaicheng Machinery Equipment Co., Ltd.

In modern mining and construction projects, handling hard rock materials is a challenging task. In order to solve this problem, the hard rock impact crusher came into being and became the leader in crushing efficiency. This article will discuss the working principle, advantages and application of hard rock impact crusher in engineering practice.

Key attributes

| Product name | Impact Crusher Machine |

| Applicable Industries | Energy & Mining, Other |

| Place of Origin |

Hebei, China

|

| Warranty |

1 Year

|

| Warranty of core components |

1 Year

|

| Marketing Type |

New Product

|

| Machinery Test Report |

Provided

|

| Video outgoing-inspection |

Provided

|

| Key Selling Points |

High-accuracy

|

| Color |

Customer’s Request

|

| Applicaton |

Mining, construction, railways, Other

|

Technical Parameters

| Specifications | Rotor diameter | Rotor length | Production | Motor Power | weight | Max feed |

| PF-1007 | 1000 | 700 | 15-30 | 37 | 6.5 | 250 |

| PF-1010 | 1000 | 1000 | 30-80 | 75 | 12.7 | 250 |

| PF-1210 | 1250 | 1050 | 60-120 | 110 | 14.5 | 300 |

| PF-1212 | 1250 | 1250 | 80-140 | 132 | 16.8 | 300 |

| PF-1214 | 1250 | 1400 | 100-160 | 160 | 19.5 | 300 |

| PF-1310 | 1300 | 1050 | 70-140 | 132 | 14.2 | 300 |

| PF-1315 | 1300 | 1500 | 100-180 | 180 | 21.5 | 300 |

| PF-1320 | 1300 | 1200 | 150-250 | 200 | 24.5 | 300 |

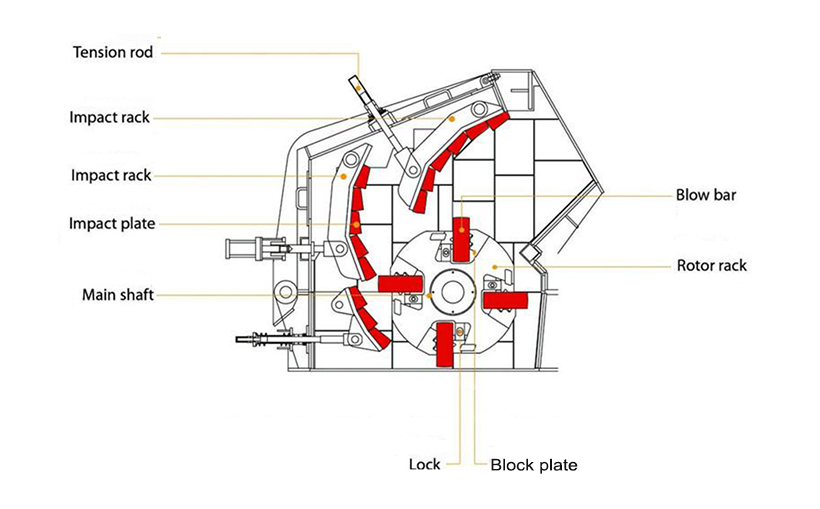

Working principle of hard rock impact crusher

The core component of the hard rock impact crusher is the high-speed rotating rotor. When the material enters the crushing chamber, it is quickly accelerated to a very high speed by the impact force of the high-speed rotating rotor, and violently collides with the fixed plate or other materials in the crushing chamber. These strong impact and friction effects quickly break the material into the required particle size.

Characteristics of hard rock impact crusher

High efficiency: The hard rock impact crusher can break materials into ideal particle sizes in a short time through high-frequency impact, and the efficiency is significantly higher than traditional crushing equipment.

Excellent particle shape: Due to the special working principle of the impact crusher, the crushed material has a more uniform particle shape and is cube-shaped, which reduces the generation of needle-shaped particles, which is of great significance for subsequent processing and use.

Wide scope of application: Hard rock impact crusher is not only suitable for high hardness ores and rocks, but also for crushing medium hardness and soft materials. It is widely used in mining, building materials, highways, railways, water conservancy and chemical industries.

Strong wear resistance: The equipment is made of high wear-resistant materials, and the main components such as the rotor, crushing plate, etc. have a long service life, reducing the frequency of maintenance and replacement, and improving the economy of the equipment.

Easy operation and maintenance: The hard rock impact crusher has a simple structure, is easy to operate and maintain, and has a high degree of automation, which can reduce labor intensity and improve production efficiency.

Application of hard rock impact crusher

Hard rock impact crushers have wide application prospects in the mining industry. It can effectively crush hard rocks such as granite, basalt, and diabase, providing an efficient crushing solution for mining and mineral processing. Hard rock impact crushers also play an important role in construction waste treatment, sand and gravel production and cement industry.

Future development of hard rock impact crusher

As the depth of mining resources continues to increase, the hardness and abrasiveness of the rocks faced are also increasing. Hard rock impact crushers will further develop in the direction of high efficiency, energy saving and environmental protection in the future. Through technological innovation and optimized design, it can not only improve the crushing efficiency of the equipment, but also reduce energy consumption and environmental pollution. In addition, the introduction of intelligent and automated technology will make the operation of the hard rock impact crusher more convenient and improve the level of production management.

Company Profile

The company is located in Xingtang Economic Development Zone, Shijiazhuang, Hebei Province. The company has been committed to the research, design, development and manufacturing of various types of dust collectors, magnetic separators, vibrating screens, dryers, sand washers, conveyors, etc. Mining Equipment. The company adheres to the concept of “technology first, integrity first”.

Technical strength:

Huaicheng Machinery has an efficient team composed of experienced engineers and technical experts, constantly pursuing technological innovation and product upgrades. In terms of mechanical structure design and automated control systems, Huaicheng Machinery has always maintained a leading position in technology.

Manufacturing process:

Huaicheng Machinery has advanced production equipment and a strict quality control system to ensure that every piece of equipment can meet customer requirements. The company focuses on the refinement and standardization of production processes, using advanced processing techniques and sophisticated testing methods to ensure product stability and reliability.

Customer service:

Huaicheng Machinery always puts customer needs first and takes satisfying customer needs as its own responsibility.

Looking to the future:

As an enterprise that constantly pursues excellence, Huaicheng Machinery will continue to adhere to the purpose of “quality first, customer first”, continuously improve its technical strength and service levels, and provide customers with better industrial solutions. In the future, Huaicheng Machinery will continue to be committed to technological innovation and product upgrading, and work hand in hand with customers to create a better future together!

Hebei Huaicheng Machinery Equipment Co., Ltd. looks forward to working with you to create brilliance together!

Pack and ship

The machine is wrapped in film, which is effectively waterproof and dustproof. When the machines arrive at your facility, they will be clean and brand new.

FAQ

1.Who are where?

We are headquartered in Hebei, China, starting in 2020, selling to South Asia (20.00%), East Asia (20.00%), MiddleEast (10.00%), Southeast Asia (10.00%), North America (10.00%). There are about 201-300 people in our office in total.

2. How do we ensure quality?

Before mass production is always a pre-production sample;

Always conduct final inspection before shipment;

3. What can you buy from us?

Dust collector, magnetic extractor, linear vibrating screen, sand washing machine, drum dryer.

4. Why should you buy from us instead of other suppliers?

The company adheres to the concept of “technology first, integrity first” and has won the trust of our customers with technologyand product quality, reasonable prices, and timely service.

5. What services can we provide?

Accept delivery terms: FOB, CFR, CIF, EXW, CIP, FCA, DDP;

Accepted payment currencies: US dollars, euros, Japaneseyen, Canadian dollars, Hong Kong dollars, British pounds, RMB;

Accepted payment methods: T/T, L/C, Western Union;

Spokenlanguages: English, Chinese, Japanese

Post time: May-16-2024