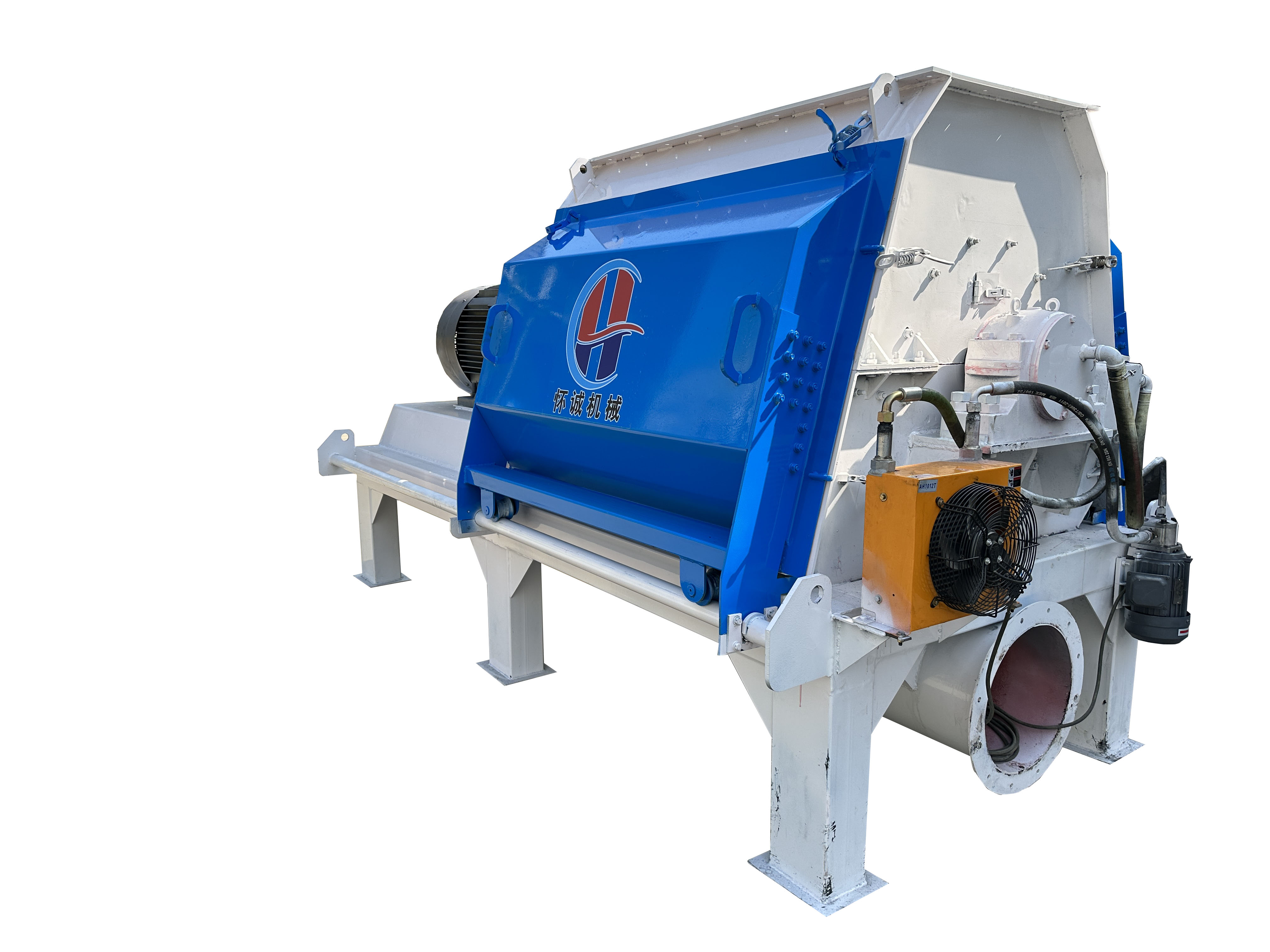

Hammer crusher helps waste recycling

Xingtang Huaicheng Machinery Equipment Co., Ltd.  CN

CN

Production

In modern agricultural production, the use of mechanical equipment has become the key to improving production efficiency and reducing labor intensity. Among many agricultural machinery and equipment, hammer crushers are popular for their efficient crushing capabilities and wide range of applications.

Key attributes

| Max. Capacity | 1t/h |

Other attributes

| Applicable industries | Machinery repair shop, others |

| Showroom Location | None |

| Origin | Hebei china |

| Weight | 1800kg |

| Main selling points | High precision |

| Marketing Type | New Products |

| Video outgoing-inspection | Provide |

| Machinery Test Report | Provide |

| Color | can be customized |

| Function | Easy to operate and high efficiency |

| Warranty of core components | 1year |

| Key words | hammer mill |

Product Description

Hammer crusher is one of the important equipment in the biomass pellet production line. Hammer crusher can be used to crush corn stalks, straw, grass, sawdust, wood, branches and other waste. Adopt internal cooling structure to avoid mechanical damage caused by high temperature caused by friction. It has the characteristics of reasonable structure, sturdy and durable, safe and reliable, easy to operate, small vibration and high efficiency. Mainly used in lumber mills, feed mills, breeding plants, organic fertilizer plants, medicine, chemical industry and other industries.

Application areas

Livestock and poultry feed processing: Hammer crusher is an important equipment for processing feed. It can crush corn, soybeans, wheat bran and other crop materials into particles suitable for livestock and poultry consumption.

Crop Residue Disposal: After crops are harvested, crop residue disposal is critical for soil conservation and reuse. A hammer crusher can break these residues into fine particles to facilitate soil decomposition and recycling.

Biomass energy production: Biomass energy, such as sawdust, straw, etc., can be used for biomass energy production after crushing, such as biomass pellet fuel and biomass fuel power generation.

Hammer crusher features

High efficiency and energy saving: Hammer crusher can crush various raw materials efficiently, with low energy consumption and high production efficiency.

Versatility: suitable for crushing a variety of raw materials and has a wide range of applications.

Maintenance costs: Although hammer crushers perform well in the crushing process, their maintenance and upkeep are also crucial. The wear of blades, bearings and other components should be checked regularly to ensure the normal operation of the equipment.

Cutting styles and versatility

Hammer crushers use a variety of cutting methods, such as hammer head rotation, hammer head impact, drum crushing, etc. This diverse design enables the equipment to adapt to different types of plant materials and raw materials, providing greater flexibility and adaptability . Whether you’re processing straw bales, corn stover or lumber, a hammer crusher gets the job done efficiently.

Technical Parameters

Large hammer mill

| Model | PowerPower(kw) | Production Capacity(t/h) | Hammer Qty | Dimension(m) |

| 50-4 | 22 | 1 | 32 | 1400*800*1250 |

| 60-6 | 37+7.5 | 1-1.2 | 56 | 1800*900*1550 |

| 80-8 | 55+11 | 1.5-2 | 80 | 2200*1800*1500 |

| 80-12 | 90+15/110+15 | 3-4 | 180 | 2300*2300*1500 |

| 90-15 | 132+15 | 4-5 | 240 | 2500*2600*2200 |

Single/double rotor hammer mill

| Model | Power(kw) | Capacity(t/h) | Hammer O t y | Dimensions(m) | Weight(t) |

| YFCZ 40 | 7.5 | 0.2-0.5 | 12 | 71310×800×1070 | 0.2 |

| YFCZ 50 | 15 | 0.6-0.8 | 16 | 1380×800×1070 | 0.45 |

| YFCZ65×27 | 22 | 0.8-1.5 | 24 | 1500×1000×1100 | 1.1 |

| YFCZ 65×55 | 37-45 | 1-2 | 48 | 1700×1000×1100 | 1.7 |

| YFCZ 65×75 | 55-75 | 2-3 | 72 | 2100×1000×1100 | 2.2 |

| YFCZ 65×100 | 90-110 | 3-4 | 96 | 2400×1000×1100 | 2.6 |

| YFCZ 130×55 | 110-160 | 5-6 | 80 | 2800×1620×2100 | 5.6 |

| YFCZ 130×100 | 160-220 | 7-8 | 160 | 3020×1620×2170 | 7.1 |

Company Profile

The company is located in Shijiazhuang Xingtang Economic Development Zone, Hebei Province.The company has been committed to the research, design, development and manufacture of all kinds of dust remover, magnetic separator, vibrating screen, dryer, sand washing machine, conveyor and other mining equipment.The company abides by the concept of “technology first, honesty first”, and wins the trust of customers with its technology and product quality, reasonable price and timely service.

Post time: Mar-17-2024