Xingtang Huaicheng Machinery Equipment Co., Ltd.

Key attributes

| Product name | High Weir Spiral Classifier |

| After sale service | Video Technical Support |

| Motor | Different models |

| Condition | New |

| Key Selling Points | High Rigidity |

| Core Components | Motor, Other |

| Warranty of core components | 1 Year |

| Video outgoing-inspection | Provided |

| Machinery Test Report | Provided |

| Marketing Type | New Product |

| Place of Origin | Hebei, China |

Technical Parameters

| Specifications and models | Sand return(t/24) | Overflow(mm) | Speed (rev/min) | Motor Power(kw) | Weight(t) |

| 7-G-7.5 | 340-570 | 65 | 6-10 | 5.5 | 2.8 |

| 7-G-10 | 675-1080 | 110 | 5-8 | 7.5 | 3.9 |

| 7-G-12 | 1170-1870 | 155 | 5-8 | 11 | 7.0 |

| 7-G-15 | 1830-2740 | 235 | 4-6 | 15 | 12.5 |

Working Principle

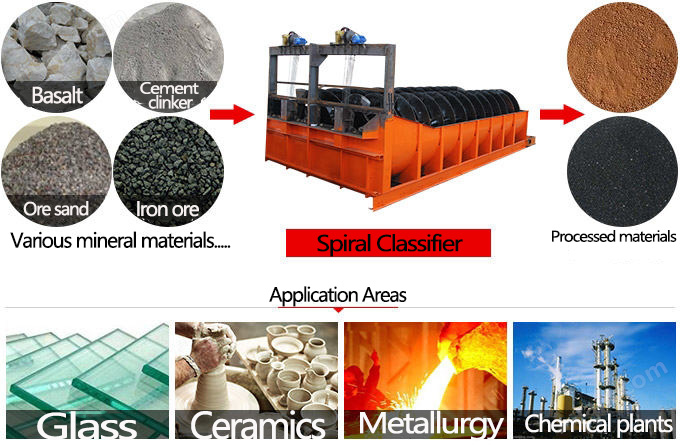

The working principle of the high weir spiral powder separator is that according to the different settling speeds of different mineral particles in the liquid, when the slurry enters the tank, the larger particles are deposited at the bottom of the tank due to the faster settling speed, and are lifted to the upper part by the rotation of the spiral blades for discharge; the smaller particles are discharged with the overflow of the water flow, thus realizing particle classification.

Main Features

High weir design: The high weir spiral powder separator adopts a higher weir design, which can better control the overflow particle size and is suitable for the classification of fine-grained materials.

Simple structure: The equipment structure is relatively simple, easy to maintain, and has low operating costs.

High classification efficiency: By reasonably adjusting the inclination angle of the tank and the spiral speed, the classification efficiency can be improved and the product quality can be guaranteed.

Application Fields

Mineral processing: used for the classification of ores after grinding, such as iron ore, gold ore, copper ore, etc.

Sand and gravel production: used for the classification of machine-made sand and natural sand.

Coal industry: used for the classification and dehydration of coal slime.

Chemical industry: used for the classification of powdered materials.

Operation and maintenance

Regular inspection: Regularly check the wear of the spiral blades, transmission devices and troughs, and replace worn parts in time.

Lubrication maintenance: Regularly add lubricating oil to the transmission device to ensure its normal operation.

Clean up debris: Keep the inside of the trough clean to prevent debris from clogging and affecting the operation of the equipment.

Development trend

With the continuous advancement of mineral processing technology, spiral powder separators have new development trends in automation, energy saving and environmental protection. Modern Gaoyan spiral powder separators are equipped with automatic control systems, which can realize remote monitoring and operation and improve work efficiency. In addition, the improvement of equipment materials and the application of new wear-resistant materials have further improved the performance and service life of the equipment.

Company Profile

The company is located in Xingtang Economic Development Zone, Shijiazhuang City, Hebei Province. The company has been committed to the research, design, development and manufacturing of various types of dust collectors, bale crushers, pellet machines, hammer crushers, jaw crushers, shredders, magnetic separators, vibrating screens, dryers, sand washers, conveyors and other mining and livestock equipment.

Technical Strength:

Huaicheng Machinery has an efficient team of experienced engineers and technical experts, constantly pursuing technological innovation and product upgrades.

Manufacturing Process:

Huaicheng Machinery has advanced production equipment and a strict quality control system to ensure that each equipment can meet customer requirements.

Customer Service:

Huaicheng Machinery always puts customer needs first and takes it as its responsibility to meet customer needs.

Pack and ship

The machine is wrapped in film, which is effectively waterproof and dustproof. When the machines arrive at your facility, they will be clean and brand new.

FAQ

1. Who are we?

We are headquartered in Hebei, China, starting in 2020, selling to South Asia (20.00%), East Asia (20.00%), Middle East (10.00%),Southeast Asia (10.00%), North America (10.00%). There are about 201-300 people in our office in total.

2. How do we ensure quality?

Before mass production is always a pre-production sample;

Always conduct final inspection before shipment;

3. What can you buy from us?

Dust collector, magnetic extractor, linear vibrating screen, sand washing machine, drum dryer.

4. Why should you buy from us instead of other suppliers?

The company adheres to the concept of “technology first, integrity first” and has won the trust of our customers with

technology and product quality, reasonable prices, and timely service.

5. What services can we provide?

Accept delivery terms: CFR、CIF、EXW、CIP、FCA、DDP;

Accepted payment currencies: US dollars, euros, Japanese, Canadian dollars, Hong Kong dollars, British pounds, RMB;

Accepted payment methods: T/T, L/C, Western Union;

Spoken Languages: English, Chinese, Japanese

Post time: May-30-2024