Precision Feeding: Advancements in Trailed Vertical Mixers for Livestock

Vertical feed mixer to improve production efficiency

Hebei Xingtang Huaicheng Machinery Equipment Co., Ltd.

In animal husbandry and breeding, the quality of feed directly affects the growth and health of animals. In order to ensure that the feed is evenly mixed, the ingredients are fully mixed, and to improve production efficiency, the vertical feed mixer has become an indispensable piece of equipment in the modern breeding industry.

Key attributes

| Max. Capacity | 5 ton/h |

Other attributes

| Applicable industries | farms, poultry farms |

| Showroom Location | None |

| Origin | Hebei china |

| Weight | 2000kg |

| Warranty | 1 year |

| Main selling points | automatic |

| Mechanical test report | Provide |

| Video outbound inspection | Provide |

| Core component warranty | 1 year |

| Core components | Gearbox, motor, blade |

| Situation | New |

| Dimensions (length*width*height) | 3800*2000*2300mm |

| Color | green/can be customized |

| Package | Wooden box/naked package/customer setting |

Technical Parameters

| Type | Dimensions(L*W*H) | Production | Motor |

| 9JGL-5 | 3150×2150×2290mm | 3T/H | 18.5KW |

| 9JGL-9 | 4400×2350×2700mm | 5-6T/H | 30KW |

| 9JGL-12 | 4500×2550×2800mm | 5-6T/H | 37KW |

| 9JGL-21 | 6200×2250×2950mm | 5-6T/H | 37KW |

| 9JGL-24 | 7300×2400×2900mm | 5-6T/H | 37*2KW |

| 9JGL-36 | 8550×2500×2950mm | 6-10T/H | 37*2KW |

| 9JGL-48 | 11000×3250×3000 | 10-12T/H | 37*4KW |

working principle

A vertical feed mixer is a machine that mixes feed ingredients of different types and proportions evenly by rotating a stirring paddle. Its working principle is based on the rotation and impact of materials during the mixing process, ensuring even distribution of various ingredients.

Rotate and stir:

The vertical feed mixer is equipped with multi-layer mixing paddles inside. When the equipment is started, the mixing paddles start to rotate, throwing the feed ingredients upward and falling freely, achieving all-round mixing.

Impact dispersion:

While rotating, the feed ingredients will also collide with each other, making the particles more tightly combined and ensuring the uniformity of the feed.

Advantages of vertical feed mixer

Mix evenly:

The vertical feed mixer can mix different types and proportions of feed ingredients more evenly, ensuring that animals receive balanced nutrition.

High production efficiency:

Because the vertical feed mixer adopts a rotating mixing method, the mixing speed is fast and the efficiency is high, which can greatly shorten the mixing time and improve production efficiency.

Energy saving:

Vertical feed mixers usually use advanced motors and energy-saving designs, which can save a lot of energy and reduce production costs compared with traditional mixing methods.

Easy to operate:

The equipment has a simple structure, is easy to operate, and does not require complicated maintenance and upkeep, reducing labor costs and the risk of equipment failure.

Ways to improve production efficiency

Optimize ingredient ratio:

Reasonably adjust the ratio of feed ingredients to ensure that the mixing time is minimized while ensuring nutrition.

Regular inspection and maintenance:

Regularly inspect and maintain the vertical feed mixer to keep the equipment in good working condition and reduce malfunctions and downtime.

Using advanced technology:

Introduce advanced automated control systems and intelligent technology to improve the automation of equipment, reduce manual intervention, and further improve production efficiency.

As an important equipment in feed processing, vertical feed mixer plays a key role in improving feed quality and improving the efficiency of livestock and poultry breeding. With the continuous advancement of technology and the continuous demand of the market, vertical feed mixers will surely play a more important role in the livestock and poultry breeding industry, injecting new impetus into the development of the industry.

Company Profile

Customer Visit

Overseas Delivery

Exhibition

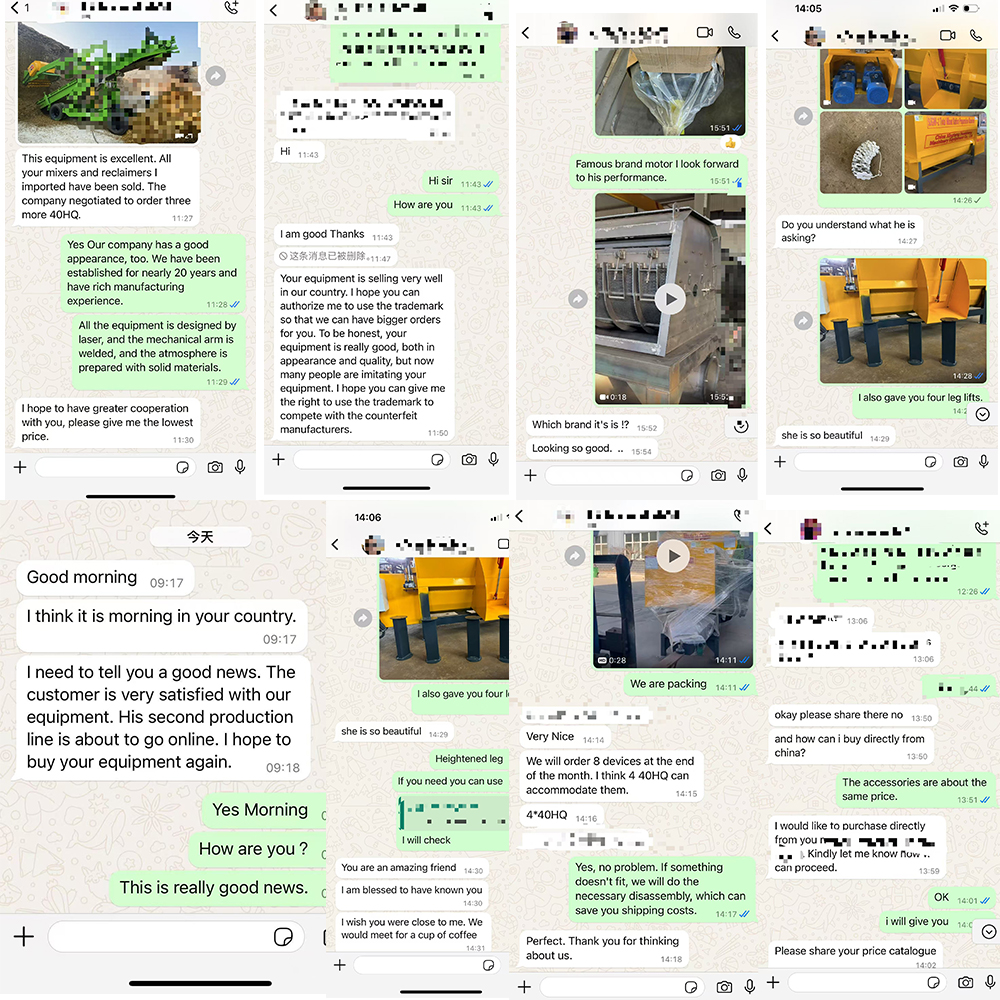

Feedback