Pressure Resistance Briquetting Machine Grass Processing Machine Stable Practical Mixing Machine Hot Sale Uniform Briquetting

Basic Information

The silage reclaimer is a kind of reclaiming equipment, which has the functions of reclaiming, conveying, chopping, etc. It is widely used in dairy farms. It is a common equipment for loading and fetching feed in cattle farms and cattle breeding areas. In recent years, with the application of feed mixers, silage reclaimers have been welcomed by dairy cow managers as supporting products of mixers. The silage reclaimer replaces the traditional artificial filling method, which saves labor costs, and the cattle farm silage reclaimer improves labor efficiency.

The silage reclaimer is the main raw material of the pasture. Because the silage is pressed relatively firmly during the stacking process, it is time-consuming and laborious to use labor in the feeding and excavation work. Using a forklift will easily cause a large area of silage to loosen and ventilate, resulting in secondary Fermentation. The silage reclaimer solves the problem of silage excavation, and is a common equipment for small and medium-sized pastures.

The use of silage is a very important part in feeding and management, because the daily silage intake of dairy cows accounts for about half of the food intake. For a thousand-head pasture, more than 20 tons of silage need to be consumed every day. It takes 4-6 labors; and when making silage, in order to effectively protect the quality, it is necessary to use tools such as forklifts to pack and compact the silage as much as possible, so that when taking silage, especially manual planing, the labor intensity is very high .

Product Advantages

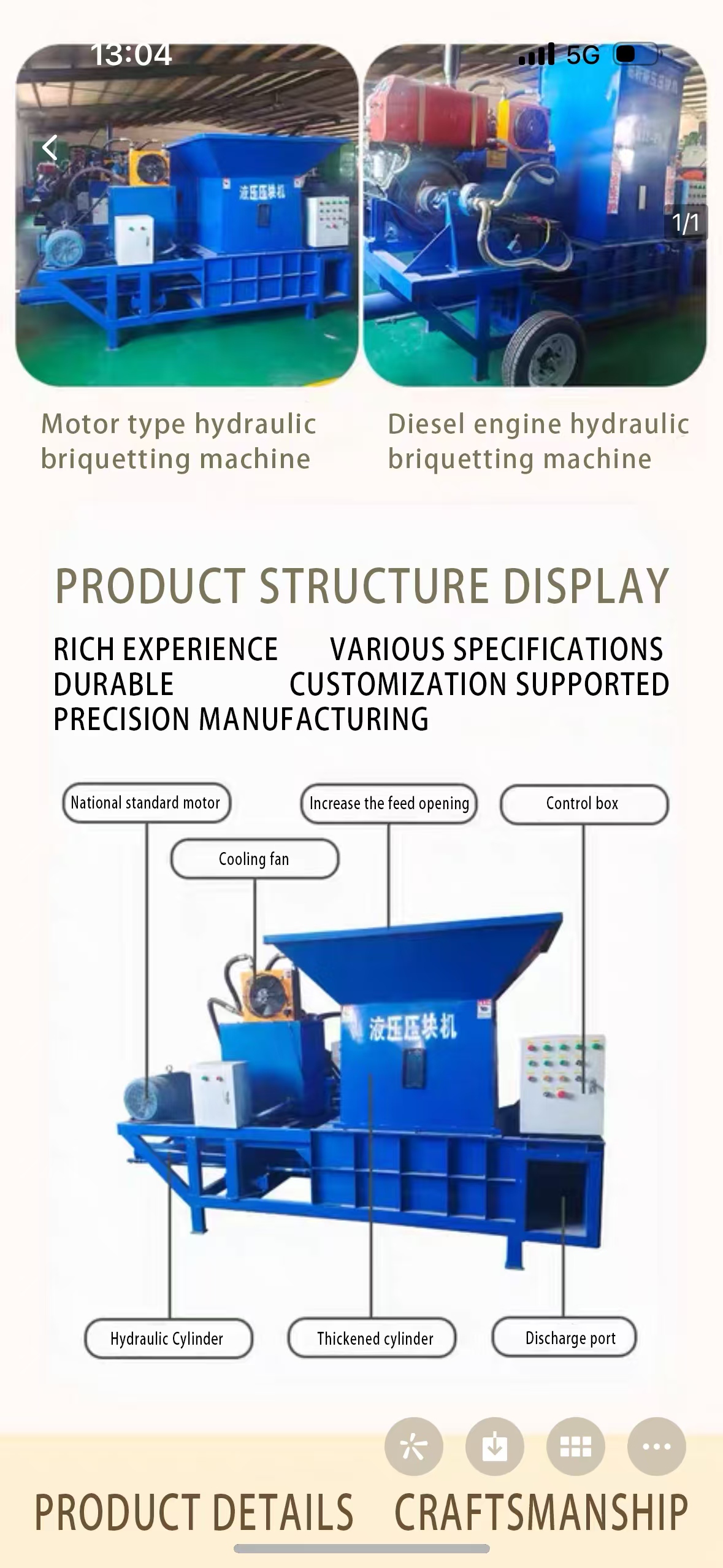

A briquetting machine is a device used to compress loose materials into dense blocks or spheres. It is widely used in industries such as biomass, metal, coal powder, and mineral powder. It compresses large waste, powder or granular materials into regular shapes through different methods such as hydraulic, mechanical or high pressure, so as to facilitate transportation, storage or subsequent processing. The briquetting machine can not only improve the utilization rate of materials and reduce the volume of waste, but also reduce transportation and storage costs and improve production efficiency.

Depending on the material, briquetting machines can be divided into biomass briquetting machines, metal briquetting machines, coal powder briquetting machines and other types. The equipment has a compact design and a solid structure. It usually adopts automatic control and has the characteristics of high efficiency, energy saving and durability. During operation, the briquetting machine uses high pressure to make the materials tightly combined, and the molding effect is good. The pressed block material has high density and high strength, which is conducive to subsequent processing or direct application.

The briquetting machine not only saves resources and improves efficiency in industrial production, but also has good environmental benefits. By briquetting waste materials, the discharge of waste is reduced, which meets the requirements of green environmental protection in modern production and is an important equipment in the sustainable development production system.

Company Profile

Customer Visit

Overseas Delivery

Exhibition

Feedback