Provide buyers with a reliable choice of mining ball mill

Detailed Professional Introduction

Exploring ball mills: analyzing the key to ore processing

Hebei Xingtang Huaicheng Machinery Co., Ltd.

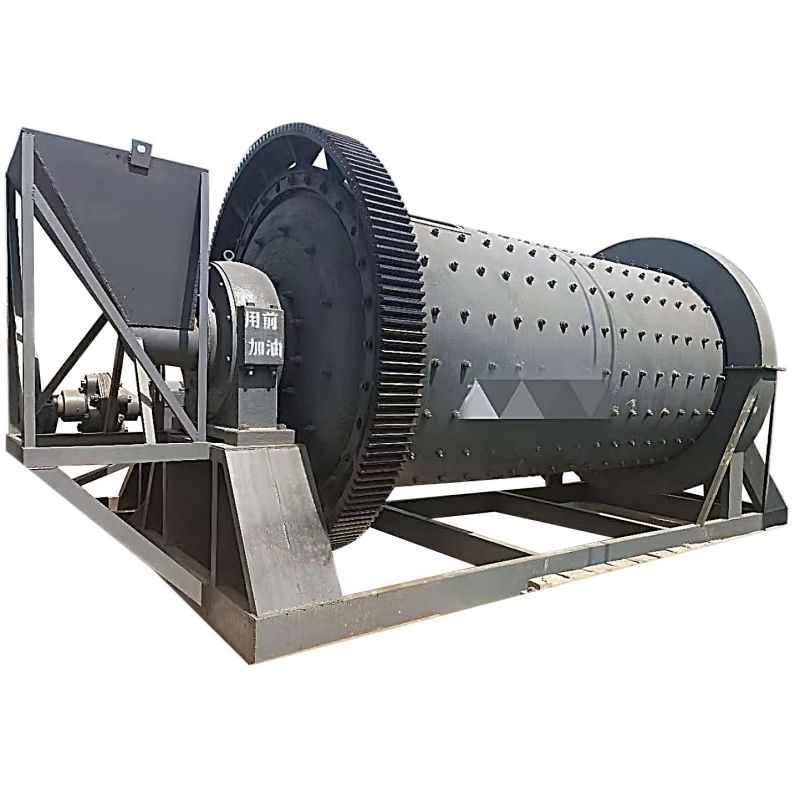

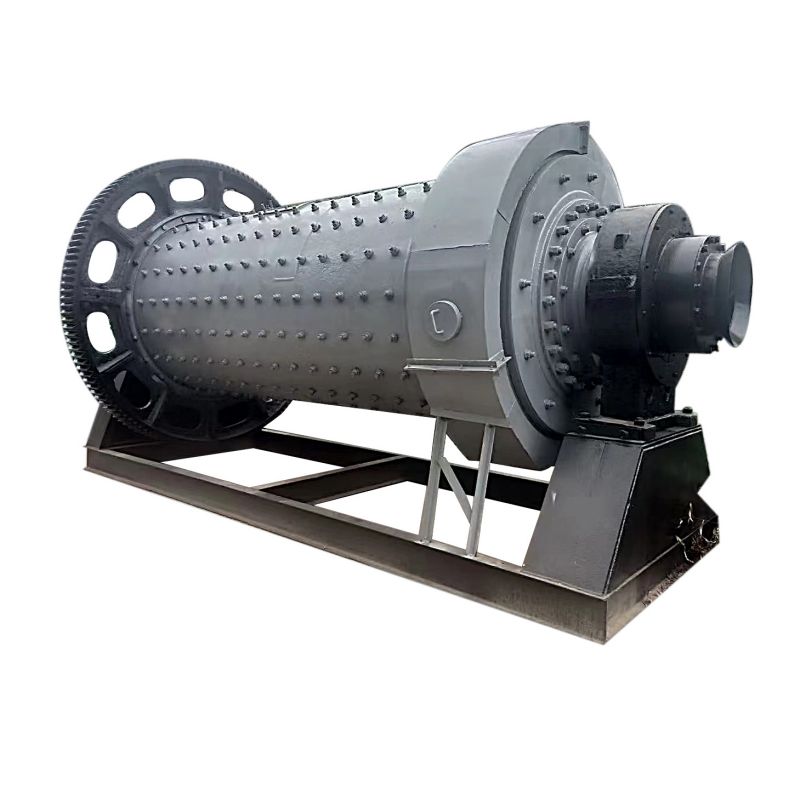

Ball mill is a vital piece of equipment used to grind various ores and other materials to refine them into smaller particles. The design and operating principles of this equipment have an important impact on the efficiency and product quality of ore processing.

Structure and Working Principle

A ball mill usually consists of a rotating cylinder and a ball filled with abrasive inside. The ore is fed into the rotating cylinder through a feeding device, and is then ground and refined under the action of the balls inside. The size and material of the abrasive are selected to achieve the desired level of refinement.

The rotational motion of the ball mill causes the abrasives to continuously collide and rub within the cylinder, so that the ore is gradually ground into smaller particles. This grinding process is a continuous process until the desired particle size is reached.

Application areas

Ore grinding: The most common application is to grind raw ore into finer particles for subsequent beneficiation processes. The refinement of ore can improve beneficiation efficiency and improve metal recovery.

Cement Production: Ball mills are also widely used in the cement production process. In cement production, ball mills are used to grind clinker into cement clinker, and to grind raw materials in the mixture into the required powdery substance.

Chemical industry: Ball mills are also widely used in the chemical industry for grinding various chemical raw materials, such as pigments, coatings and fertilizers, etc., to achieve the required particle size and particle morphology.

Technological innovation and development trends:With the continuous advancement of science and technology, the design and performance of ball mills are also constantly improved and optimized.

Automated control system: Modern ball mills are usually equipped with advanced automated control systems, which can achieve precise control and regulation of the grinding process, improve production efficiency and ensure product quality.

Wear-resistant materials and lubrication technology: The application of new wear-resistant materials and lubrication technology can extend the service life of the ball mill and reduce maintenance costs.

Energy conservation and environmental protection: Ball mill manufacturers are paying more and more attention to energy conservation and environmental protection, and are committed to developing new ball mill equipment that can reduce energy consumption and reduce emissions.

As an indispensable equipment in mining and other industrial fields, ball mill plays an important role in the ore processing and grinding process. With the continuous advancement and innovation of technology, the performance and efficiency of ball mills will be further improved, bringing greater convenience and benefits to mining and industrial production.

Company Profile

The company is located in Xingtang Economic Development Zone, Shijiazhuang, Hebei Province. The company has been committed to the research, design, development and manufacturing of various types of dust collectors, magnetic separators, vibrating screens, dryers, sand washers, conveyors, etc. Mining Equipment. The company adheres to the concept of "technology first, integrity first".

Technical strength:

Huaicheng Machinery has an efficient team composed of experienced engineers and technical experts, constantly pursuing technological innovation and product upgrades. In terms of mechanical structure design and automated control systems, Huaicheng Machinery has always maintained a leading position in technology.

Manufacturing process:

Huaicheng Machinery has advanced production equipment and a strict quality control system to ensure that every piece of equipment can meet customer requirements. The company focuses on the refinement and standardization of production processes, using advanced processing techniques and sophisticated testing methods to ensure product stability and reliability.

Customer service:

Huaicheng Machinery always puts customer needs first and takes satisfying customer needs as its own responsibility.

Looking to the future:

As an enterprise that constantly pursues excellence, Huaicheng Machinery will continue to adhere to the purpose of "quality first, customer first", continuously improve its technical strength and service levels, and provide customers with better industrial solutions. In the future, Huaicheng Machinery will continue to be committed to technological innovation and product upgrading, and work hand in hand with customers to create a better future together!

Hebei Huaicheng Machinery Equipment Co., Ltd. looks forward to working with you to create brilliance together!

Our Factory

Company Profile

Customer Visit

Overseas Delivery

Exhibition

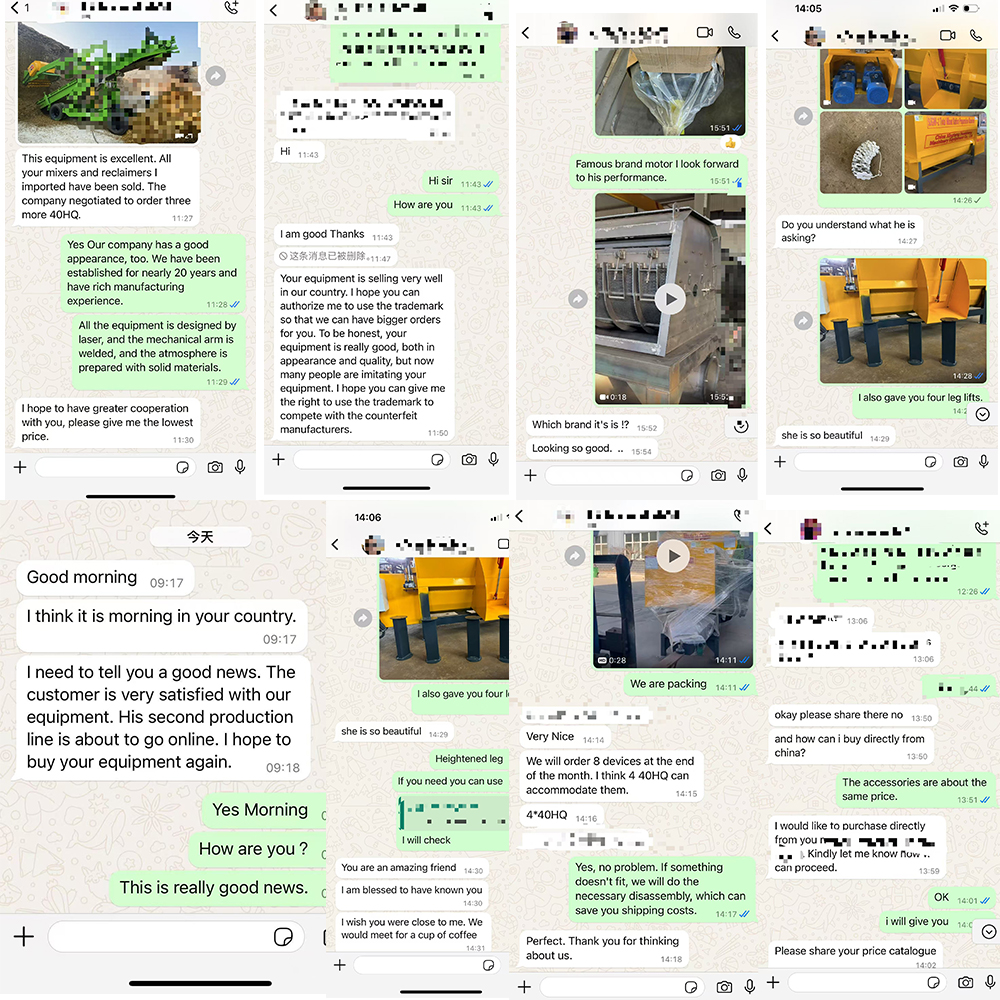

Feedback