Rotary Dryer Machine Industry Rotary Dryer Furnace Drying Stove

Description details

Drying furnace: key equipment to improve ore processing efficiency

Hebei Xingtang Huaicheng Machinery Equipment Co., Ltd.

Working principle of drying oven:

Drying furnaces are mainly used in mineral processing, building materials, metallurgy, chemical industry and other departments to dry materials with a certain humidity or particle size. It is a commonly used mining machinery and equipment. The drying furnace has reliable operation, flexible operation, strong adaptability and large processing capacity. The drying oven may also be called a drum drying oven. Both ends of the drying oven host are highly sealed, which is energy-saving and environmentally friendly.

Drying oven application:

The wet materials are sent to the hopper by a belt conveyor or bucket elevator, and then enter the feeding end through the feeding tube of the hopper feeder. The inclination angle of the feeding pipe should be greater than the natural inclination angle of the materials so that the materials can flow into the drying furnace smoothly.

The cylinder of the drying furnace is a rotating cylinder slightly inclined to the horizontal line. Materials are supplied from the higher end. The heat carrier enters from the lower end and contacts the materials in counter-current flow. Part of the heat carrier and the materials flow into the cylinder together. As the cylinder rotates, the material moves downward under the action of gravity. When the wet materials move forward in the barrel, they receive the heat from the heat carrier directly or indirectly, thereby drying the wet materials, and then are sent out at the discharge end through a belt conveyor or screw conveyor.

The inner wall of the barrel is equipped with lifting blades, which can lift and disperse the materials, increase the contact surface between the materials and the airflow, improve the drying speed and push the materials forward. Heat carriers are generally divided into hot air, flue gas, etc. After the heat carrier passes through the drying furnace, a cyclone dust collector is generally required to capture the materials in the gas. If you need to further reduce the dust content of the exhaust gas, it should be discharged through a bag dust collector or a wet dust collector.

Advantages of drying oven:

Its performance is stable and good, its energy consumption is relatively low, and it has a wide range of uses. The drying area of the drying furnace is divided into several. Multiple drying zones not only increase drying power, but also save energy and reduce consumption. In addition, the performance of drying ovens is much stronger than traditional dryers, the performance is more stable, the operation is easier, and the drying time is shorter. This is why drying ovens are so widely used.

Example 1: After the coal in this coal factory is dried by the rotary drying furnace, the fly ash is absorbed by the dust collector, and the dried material is discharged from the lower outlet, and the dried product is transported to the designated position by the conveyor.

Example 2: This is the supporting facility of the sand factory. After the sand is washed by the sand washing machine, it is screened. However, the surface moisture of the material is very large, and it needs to be dried in a rotary drying furnace.

Company Profile

Customer Visit

Overseas Delivery

Exhibition

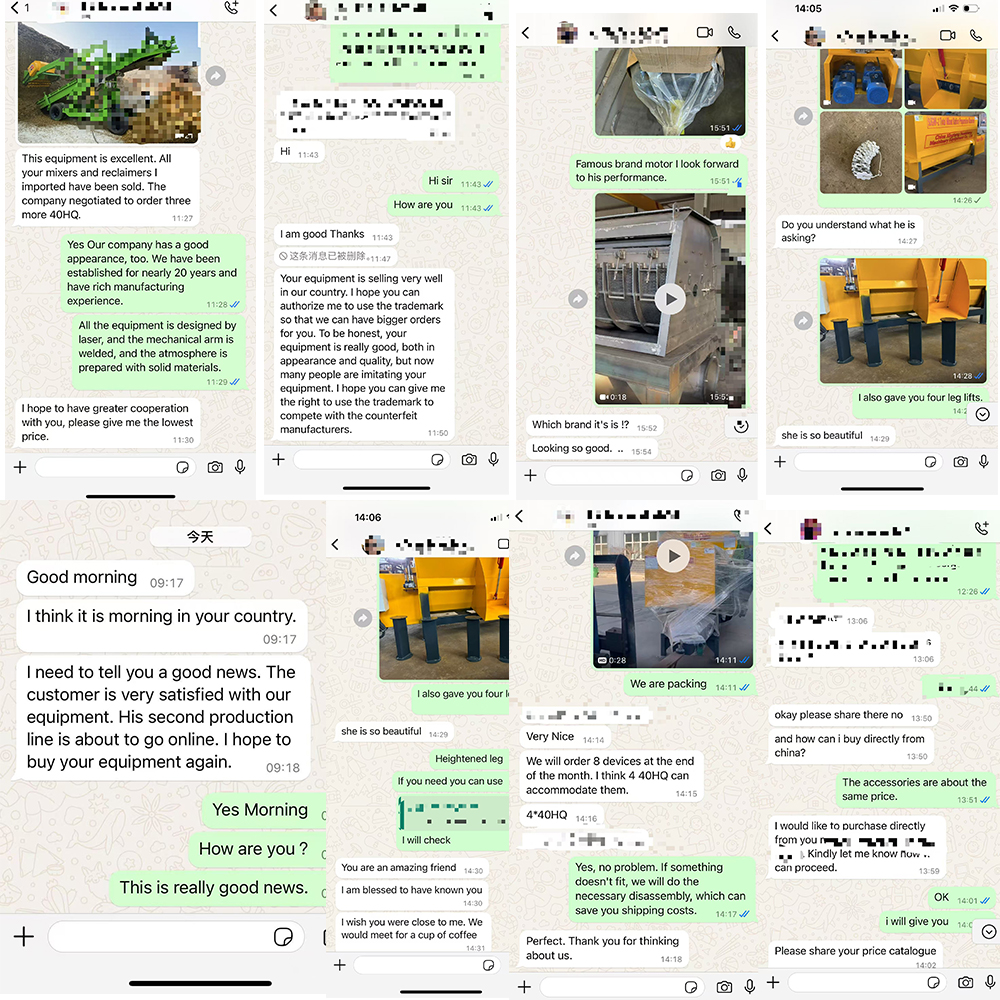

Feedback