Vibrating Sieve Filter Machine - Pellet Feed Machine Animal Feed Food Exruder Pelletizer – Xingtang Huaicheng

Vibrating Sieve Filter Machine - Pellet Feed Machine Animal Feed Food Exruder Pelletizer – Xingtang Huaicheng Detail:

Product Advantages

1. Simple structure, wide applicability, small footprint and low noise.

2. Powdered feed and grass powder can be granulated without (or a little) liquid addition. Therefore, the moisture content of pelleted feed is basically the moisture content of the material before pelleting, which is more conducive to storage.

3. The particles made by this machine have high hardness, smooth surface and sufficient internal curing, which can improve the digestion and absorption of nutrients, and can kill general pathogenic microorganisms and parasites. It is suitable for raising rabbits, fish, ducks and experimental animals. The economic benefits that can be obtained compared to mixed powdered feeds.

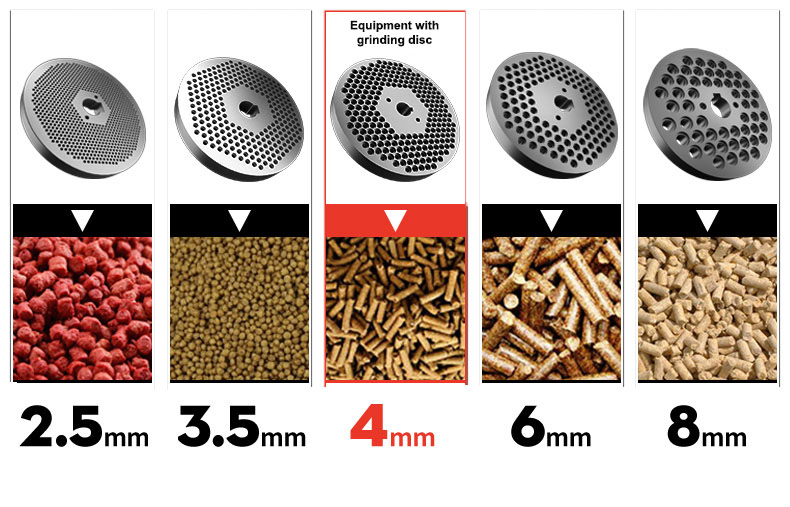

4. This model is equipped with 1.5-20 kinds of aperture molds, which are suitable for granulation of different materials and achieve the best effect.

5. Adapt to different materials to ensure the pressing effect. Compression molding of wood chips, corn stalks, etc. requires a lot of pressure. In the same kind of pelletizing equipment, the roller part is the central part of the whole equipment, and the alloy steel is used to improve the service life of the roller.

Specifications

| Model | Power(KW) | Yield(KG) | Rotating Sspeed | Dimensions(mm) | Weight |

| 120 | 3 | 40-50 | 320 | 1040*550*1140 | 68 |

| 150 | 4 | 75-125 | 320 | 1280*600*1250 | 92 |

| 210 | 11 | 200-250 | 320 | 1500*850*1400 | 189 |

| 260 | 15 | 350-500 | 380 | 1980*800*1600 | 300 |

| 300 | 18.5 | 500-800 | 380 | 2080*900*1750 | 410 |

| 400 | 37 | 1200-1500 | 400 | 2200*1200*1950 | 600 |

Instructions

1. The gearbox can be turned on after adding hyperbolic gear oil.

2. Install the pellet machine smoothly, check whether the steering meets the requirements, whether the screws in each part are loose, loosen the clearance adjustment screws on the roller axle seat, and make the feed machine in a no-load state, and it can be put into use after starting and running normally.

3. Before the new machine is used for the first time, take 10 catties of sawdust or grass powder vegetable oil or waste oil and mix it evenly, and then turn the clearance adjustment screw. Make the two rollers rotate at the same speed, gradually add the refueling feed, and at the same time continue to screw the adjusting screw of the pressing wheel until the material is slowly discharged, the extruded pellets are repeatedly squeezed to make the grinding hole smooth and smooth, and then the required mixed feed is processed. .

4. During feed processing, if there are more refined fibers, about 5% of water should be added. If there are too many concentrates in the mixed feed, the amount of water added can be reduced as appropriate. After processing, add a little oil that has been mixed with edible oil in advance. It is beneficial to start the machine next time and avoid the feed drying in the hole after the machine is stopped.

5. After processing, loosen the clearance adjustment screw to keep the roller in a free state. After the machine is stopped, remove the residual material accumulation in the upper and lower warehouses, especially the residual material at the bottom of the shaker to avoid damage to the bearing.

Our Factory

Product detail pictures:

Related Product Guide:

Gaining customer satisfaction is our company's aim forever. We will make great efforts to develop new and top-quality products, meet your special requirements and provide you with pre-sale, on-sale and after-sale services for Vibrating Sieve Filter Machine - Pellet Feed Machine Animal Feed Food Exruder Pelletizer – Xingtang Huaicheng , The product will supply to all over the world, such as: Toronto, Iran, Hongkong, We have 48 provincial agencies in the country. We also have stable cooperation with several international trading companies. They place order with us and export products to other countries. We expect to cooperate with you to develop a larger market.

The company account manager has a wealth of industry knowledge and experience, he could provide appropriate program according our needs and speak English fluently.