Xwd Cycloid Needle Teeth Meshing Planetary Transmission Gear Reducer

Core Introduction

The use of cycloid reducer:

The cycloidal pinwheel reducer adopts the principle of cycloid pin-tooth meshing and planetary transmission, so it is usually called a planetary cycloid reducer. The planetary cycloidal pinwheel reducer can be widely used in petroleum, environmental protection, chemical industry, cement, transportation, Textile, pharmaceutical, food, printing, hoisting, mining, metallurgy, construction, power generation and other industries, as a drive or deceleration device, the machine is divided into horizontal, vertical, biaxial and direct-connected assembly methods. Its unique stable structure can replace ordinary cylindrical gear reducers and worm gear reducers in many cases. Therefore, planetary cycloid reducers are widely used in various industries and fields, and are generally welcomed by the majority of users.

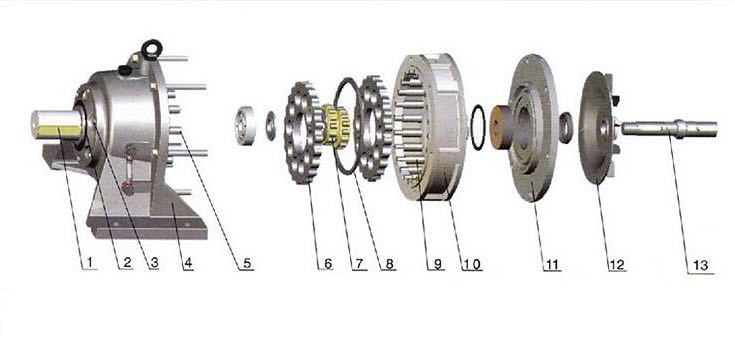

The cycloidal pinwheel reducer is a novel transmission device that applies the principle of planetary transmission and adopts the meshing of cycloid pin teeth. The entire transmission device of the cycloid reducer can be divided into three parts: the input part, the deceleration part, and the output part. A double eccentric sleeve with a dislocation of 180° is installed on the input shaft, and two roller bearings called swing arms are installed on the eccentric sleeve to form the H mechanism and the center hole of the two cycloidal wheels is the upper swing arm bearing of the eccentric sleeve The raceway, and the cycloidal wheel meshes with a group of annularly arranged needle teeth on the needle gear to form an internal meshing deceleration mechanism with a tooth difference of one tooth (in order to reduce friction, in a reducer with a small speed ratio , with needle sleeves on the needle teeth).

|

1 |

Output Shaft |

|

2 |

Output shaft tightening ring |

|

3 |

Small End Cap |

|

4 |

Machine Base |

|

5 |

Pin Bushing |

|

6 |

Cycloid |

|

7 |

Eccentric bearing |

|

8 |

Spacer Ring |

|

9 |

Pin-tooth pin pin-tooth sleeve |

|

10 |

Needle Housing |

|

11 |

Big End Cap |

|

12 |

Fan Blade Hood |

|

13 |

Input Shaft |

Our Factory

Our factory currently enjoys a robust position in the export market, with a notable surge in the demand for our equipment. The quality and reliability of our products have positioned us as a preferred choice for many consumers. Numerous individuals and businesses alike are opting for our offerings, recognizing the superior performance and durability that our equipment provides.

One of the key factors contributing to our success in the export market is the guarantee of manufacturing excellence that we uphold. Our factory has demonstrated unwavering commitment to producing top-tier products, backed by stringent quality control measures. This commitment not only ensures the satisfaction of our existing customers but also attracts new clients seeking reliable and high-performance equipment.

The strength of our manufacturer lies not only in the quality of our products but also in our ability to adapt to market trends and customer needs. We continuously invest in research and development to stay ahead of the curve, incorporating innovative features that set our equipment apart from the competition.

As a result of these factors, our factory is experiencing a notable upswing in exports, cementing our position as a leading player in the industry. The trust and confidence placed in our products by a growing customer base attest to the strength and credibility of our manufacturing processes. We are poised for continued success in the global market as we strive to exceed customer expectations and maintain the high standards that define our brand

Company Profile

Customer Visit

Overseas Delivery

Exhibition

Feedback